Affordable Next Generation Fiber Laser Cuts Up to 4X Faster than CO2 or Plasma

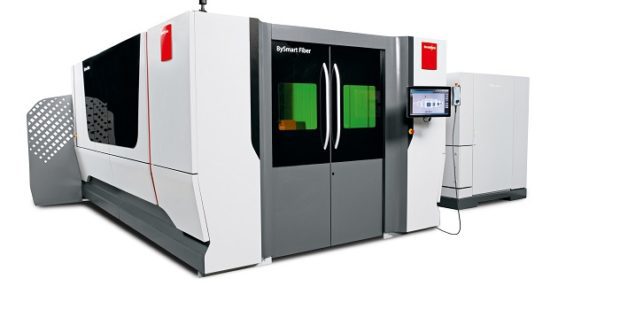

For high speed laser cutting of parts in the most simple, quickest and cost effective manner possible at an affordable price, the next generation BySmart Fiber machine from Bystronic delivers high parts output and excellent cutting quality across thin-to-medium sheet metal thicknesses.

Posted: December 8, 2018

The market for sheet metal processing is growing, with an increasing demand for new technologies. Fabricators rely on manufacturing systems that allow sheet metal parts to be processed as efficiently as possible and, at the same time, with high quality. With this in mind, Bystronic Inc. (Elgin, IL) introduces a new next generation BySmart Fiber laser cutting machine that is built from the ground up to meet the demands of high speed fiber laser cutting. The BySmart Fiber focuses on laser cutting parts in the most simple, quickest and cost effective manner possible at an affordable price. Its new machine platform meets the demands for the lowest possible operating costs and low maintenance requirements through state-of-the-art technology that delivers outstanding cutting performance for high parts output, excellent cutting quality across thin-to-medium sheet metal thicknesses, and these customer benefits:

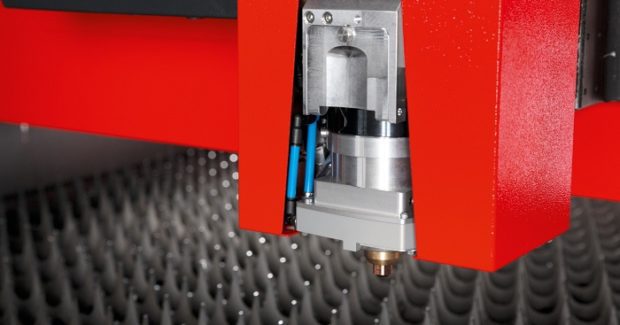

- Best-in-class fiber laser technology and total customer support. Machine platform delivers up to 4X faster cutting speeds than CO2 or plasma and uses less than half the operating costs per hour. Dual rack and pinion bridge design for fast accelerations and cutting speeds necessary for high speed laser processing. Engineered cutting head with auto focus and focal length spot size adjustment. High machine dynamics, even when cutting complex contours. More profit per part: fast cutting processes combined with comparatively low operating costs and low maintenance requirements.

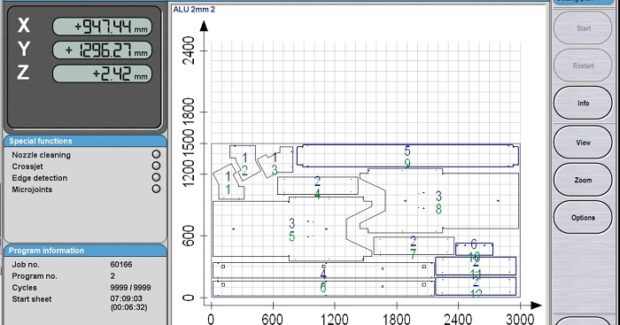

- Powerful, easy-to-use ByVision Cutting Control user interface with full 22 in touch screen controls the entire manufacturing process. Users quickly maneuver through screen selections for easy setup and operation and are seamlessly guided through the programming and manufacturing process. This interface operates within a modern MS Windows professional platform for the highest level of speed and network compatibility, and can be switched to many languages. Program data transmissions are transferred between the interface and the ByMotion CNC control utilizing high speed network communications. The integrated Condition Messenger Graphically displays the status of individual components and informs when a component should be checked. Maintenance Messenger notifies the operator when maintenance procedures are due.

To optimize material flow, improve machine use and increase work and process reliability on the new BySmart Fiber is the ByTrans Cross modular automation system for fast loading and unloading of large parts and selection of residual sheets. This automated system operates efficiently and flexibly via the operator touch screen at the laser cutting system and can be expanded at any time to fit space requirements.

Bystronic Inc., 200 Airport Road, Elgin, IL 60123, 847-214-0300, sales.us@bystronic.com, www.bystronicusa.com.