Compact, Highly Repeatable Radio Probe for Small 5-Axis Machine Tools

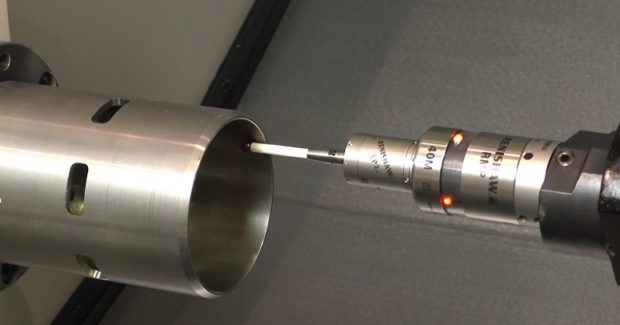

The ultra-compact RMP400 strain gauge probe from Renishaw delivers reliable, precise touch-trigger part setting, feature measurement and machine performance checking.

Posted: December 4, 2018

The RMP400 machine tool probe from Renishaw, Inc. (West Dundee, IL) is designed for small 5-axis machine tools. This ultra-compact strain gauge probe provides a reliable and precise touch-trigger system for part setting, feature measurement and machine performance checking. This RENGAGE™ probe combines proven silicon strain gauge technology with ultra-compact electronics to deliver unbeatable 3D performance and sub-micron repeatability. Excelling in the measurement of complex shapes and contours, this probe is ideally suited to mold and die and aerospace applications. An ultra-low trigger force, which helps to eliminate surface and form damage, makes it ideal for inspecting delicate workpieces. Suitable for installations where there is no line-of-sight between the spindle probe and the communication interface, the RMP400 uses radio transmission with frequency-hopping spread spectrum technology (FHSS) that enables devices to avoid interference and transmission dead spots, allowing the RMP400 to perform with impressive reliability even in high-density radio frequency environments.

Renishaw Inc., 1001 Wesemann Drive, West Dundee, IL 60118, 847-286-9953, www.renishaw.com.