Custom Turnkey, Small and Economical Deep Hole Drilling Systems

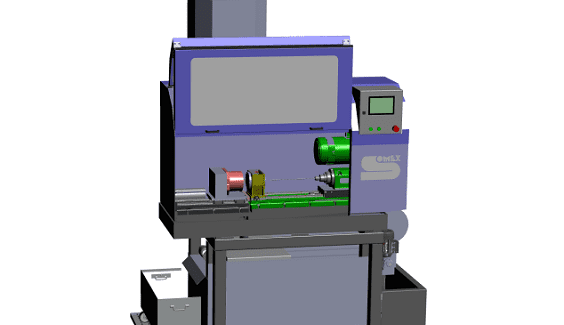

Somex deep hole drilling systems from Suhner can be integrated directly into transfer machines, special purpose equipment or conventional turning centers.

Posted: December 5, 2018

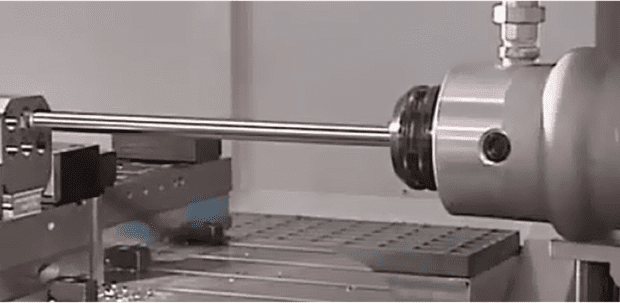

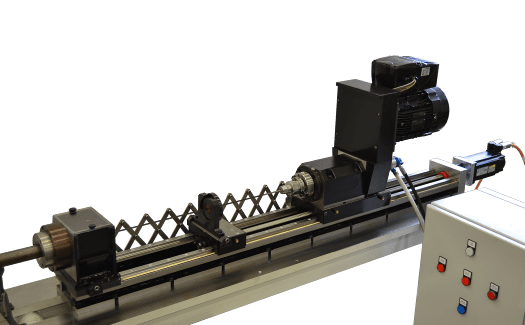

Investments in conventional deep hole drilling machines can be very expensive. The Somex division of Suhner Industrial Products Corporation (Rome, GA) offers custom-made turnkey, small and economical deep hole drilling systems capable of drilling up to 12 mm diameters as deep as 100X the diameter. These modules can be integrated directly into transfer machines, special purpose equipment or conventional turning centers. The potential for cost savings is substantial. In addition to standard MAX machining units, Somex offers peripheral components. Factory tests are routinely conducted with actual tools and material under real production conditions to prove out the design and performance of these customized deep hole drilling solutions. Single cutting edge and carbide spiral drills up to 70X the diameter are used.

The deep hole drilling process typically requires either a pilot-drill 1.5X the diameter or a drill guide bushing that is followed by the deep hole drilling process. The unique Somex design combines the guide bushing with a chip basket, allowing both items to travel in unison. The movement of the guide bushing is air-driven to help provide much closer contact to the part while preventing the escape of the coolant medium. For longer deep hole drilling applications, it may be necessary to integrate a support bushing to stabilize the deep hole drilling tool. The degree of accuracy in a deep hole drilling application measured in the deviation from the theoretical part center line is greatly enhanced by a slow part rotation in a counter-clockwise direction.

For deep hole drilling applications above 18 mm diameter, Somex offers the option to equip its MAX machining units with drilling systems from BTA or EJEKTOR lines. In these applications, the coolant and chip management is accomplished through the spindle center. The emulsion is collected at the backend of the spindle, filtered and pressurized to re-enter the coolant system. This system is often used in high volume precision parts manufacturing, such as automotive and other industries.

Suhner also offers their BEX8 high speed machining block spindle that is capable of maintaining rigidity, precision and reliable performance at extremely high speed operations up to 25,000 rpm. The BEX8 weighs only 33 lb and features the ability to mount directly onto robotic arms for fully automated machining operations in high speed, high production departments in automotive, appliance, off-highway and other applications. The standard motor supplied is either 0.37 kW or 0.75 kW and the standard toolholder supplied is ER20. This machining spindle adapts to the UA15 slide unit via the integral mounting supports. Spindle concentricity is better than 0.01 mm.

Suhner Industrial Products Corporation, Highway 411 South at Suhner Drive, PO Box 1234, Rome, GA 30162-1234, 706-235-8046, Fax: 706-235-8045, automation.usa@suhner.com, www.suhner.com.