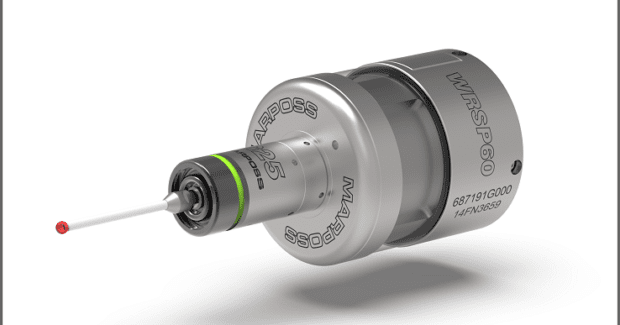

Radio Transmission Scanning Probe for Real-Time On-Machine Part Measurement

The WRSP60 high accuracy scanning probe from Marposs checks part profiles, misalignment, surface deformation, runout and more directly on machining centers and milling machines in real-time without any handling to improve the process and optimize cycle time.

Posted: December 4, 2018

The new WRSP60 high accuracy scanning probe from Marposs Corporation (Auburn Hills, MI) checks part profiles directly on machining centers and milling machines in real-time. Parts can be checked for defects without being transferred to a measurement lab, eliminating the need to reload and reposition the part for any necessary reworking, improving the process and optimizing cycle time. WRSP60 probes can be used to check the quality of the part profile, compensate for part misalignment, perform surface deformation checks providing compensation information for the cutting program, perform comparisons with the Master, check the runout, and enable the “touch” necessary for positioning the part – all operations that are impossible with touch probes or that would result in greatly increased cycle times.

The system transmits the data via radio to a WRI receiver using a communication protocol that offers excellent immunity to interference and reduced power consumption. The data is collected, analyzed and displayed by a proprietary software package. The WRSP60 also features a multi-channel system that enables the same receiver to manage up to 12 systems sequentially, including WRS part contact scanning probes that have a transmission range of 15 m, making them well-suited for large machines. They provide measurement performance on 3D surfaces with unidirectional repeatability within 0.4 µm and a better life of 80 hours continuous operation.

Marposs Corporation, 3300 Cross Creek Parkway, Auburn Hills, MI 48326, 248-370-0404, marposs@us.marposs.com, www.marposs.com.