Simulate the Entire Production Process in a Digital Factory

FASTSUITE Edition 2 3D simulation software for the digital factory from CENIT uses Industry 4.0 and the digital twin for offline programming of complex robot applications, resource building, layout planning, offline programming, PLC validation and virtual commissioning of the entire production process.

Posted: December 11, 2018

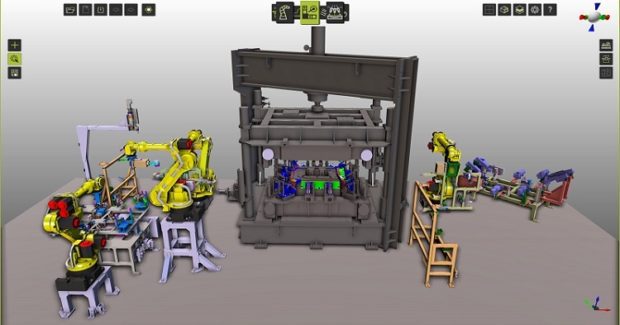

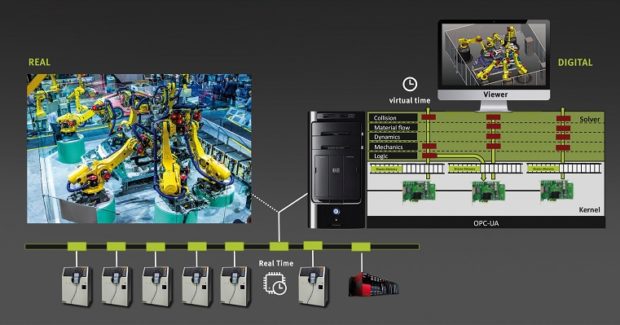

The latest version of FASTSUITE Edition 2 next-generation 3D simulation software for the digital factory from CENIT North America Inc. (Auburn Hills, MI) already scores big in offline programming of complex robot applications. Now it radically expands to include functions for layout planning, PLC validation and virtual commissioning of the entire production process, using Industry 4.0 and the digital twin for everything from Component and Layout generation all the way to Commissioning. The virtual model of the facility shown – and the real facility as well – is connected online with a FANUC robot controller and a Mitsubishi PLC. Layout generation derives from a manufacturing/assembly sequence planning system based on predefined simulation components that already exist as mechatronic models. If and when project-specific components are required, these can be added as “smart components” via a direct link to an extensive 3D manufacturer’s catalog of CADENAS PartSolutions and used immediately in simulation.

Since the entire layout is available as a mechatronic model of the production facility, the simulation environment can be used directly for PLC (programmable logic controller) validation and virtual commissioning. The virtual facility behaves in precisely the same way as the real-world hardware, as demonstrated by a Mitsubishi PLC controller, including all I/O signals, sensor data, etc. Among other benefits, this permits use of the PLC control software for testing and optimization purposes during the early stages of a project, before the real facility even exists, allowing system integrators to shorten project cycle times drastically and recognize and correct potential errors much earlier. Thanks to the integration of the virtual robot controller, the robot simulation can be done exactly as in reality and it can be done on the basis of a back-up of the real controller. This way the complex, expensive and not always available integration of RCS modules can be avoided.

CENIT North America Inc., 691 North Squirrel Road, Suite 275, Auburn Hills, MI 48326-2833, 248-309-3240, www.fastsuite.com.