A Look Ahead

As the metal fabrication business remains strong, watch for more shops to adopt digitization, the principles of Industry 4.0 and integrated process flow as they move toward smaller batch sizes, shorter lead times, high-mix parts to compete – and to address the lack of skilled labor.

Posted: January 2, 2019

Reflecting on the past year and considering the current environment, the metal fabrication business is strong, with shops inquiring about new machinery, investing in new capital equipment and very positive overall about their current and future order volumes, with solid activity in many market sectors, including construction, transportation, energy and consumer goods. The strength of this economy puts pressure on OEMs like us to deliver new lasers, press brakes, punch presses, automated machinery and other fabrication equipment in the shortest possible time. Fab shops not only want faster deliveries on everything from cost-effective machines to higher-end automated systems, they also desire more feature-rich, capable equipment with special options: systems that solve a specific issue or meet a critical need, whether it’s ultra-high speed laser cutting, bending or punching of special shapes or forms.

MAJOR TRENDS

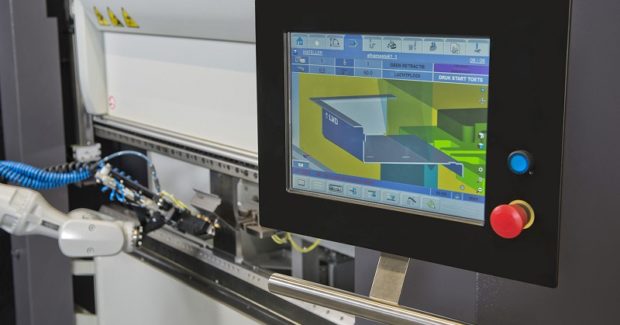

The trend toward digitization, the principles of Industry 4.0 and integrated process flow is gaining traction and will continue to influence the industry. The formal adoption of Industry 4.0 has been slow in North America, where many small to medium-sized businesses continue to think “this is just for the big companies.” But the reality is this: if a shop uses a press brake with a centralized database, they’ve already been practicing the principles of Industry 4.0, particularly if they’ve been using feedback from the controller for production planning. The mystery that surrounds Industry 4.0 is slowly unfolding and that takes education. OEMs must show their customers how to streamline their complete fabrication process, from production control, planning and management to punching, laser cutting and bending with database-driven software connected to Industry 4.0-enabled equipment – a strong “Factory of the Future” theme that was recently engaged at both the EuroBLECH and FABTECH trade shows.

The lack of skilled labor is one of the biggest issues that continues to plague our industry. The difficulty in getting qualified people for technical positions is driving fab shops to increasingly turn to technology – equipment and software – to take on more of the load, which, in turn, means OEMs must do better than simply provide technologically-advanced machinery. They must now sell complete solutions that give fabricators a quick startup and ease of use, the sort of value that is recognized by the supervisor who – in a single afternoon – is able to train a new operator with no experience to make quality, repeatable parts using a cost-effective press brake. This is possible because, no matter the level of press brake, there is technology built into the machine that simplifies startup and operation.

OEMs are ever mindful of this need to compensate for the shortage of skilled labor. It is influencing their engineering efforts as more and more fabricators talk about the move toward smaller batch sizes, shorter lead times, high-mix parts. These shops need solutions in the form of quick, easy tool changes, high-speed processing for lower cost per part production, and a wider range of automation choices, including compact material handling systems for shops with limited floor space. Every facility I visit has opportunities to optimize their process flow. When it comes to short lead times and a high product mix, a combination of automation (such as a press brake with an automated tool changer or a laser with an automatic nozzle changer) with Industry 4.0 principles can streamline the entire flow of parts, from quoting to order entry to unfolding, cutting, bending, sorting and shipping.

For example, our new Dyna-Cell robotic bending cell introduces the 10/10 rule: ten minutes for programming, ten minutes for set-up and first part production, so the user can go from “art” to “part” in only 20 minutes or less. In the year ahead, look for continually more automation such as this, in increasingly diverse applications across all types of machinery, in response to the shortage of skilled labor. Equipment setup and programming, even on base-level machines, will become ever simpler and straightforward as possible.

The uncertainty surrounding tariffs also impacts our industry, but we can only speculate at this time how they will specifically impact fabricators and OEMs. For example, last year we developed a relationship with an OEM that was sourcing all of their fabricated parts from China. Prior to the implementation of the tariffs, they ordered a laser with automation and a high-end press brake. They now appreciate the fact that they are no longer outsourcing and having to deal with the uncertainties surrounding the tariffs and outsourcing issues in general, such as quality, lead time, etc.

BOTTLENECKS OR ROADBLOCKS?

When talking to fabricators, I like to help them recognize the many opportunities for cost savings in their business – because this sometimes takes another set of eyes. To every shop that is still trying to compete using old technology, doing things the way they’ve always done them, holding on to old ways of thinking, we ask them to step back and take a hard, objective look at their processes: Are they jeopardizing business? Do they create production bottlenecks or roadblocks? If the answer is yes, the solution is very often a step up to new technology, equipment, software – investments that are proven to reap cost savings and benefits, both short and long-term. Many fabricators hesitate to make an investment in software because they fear the learning curve and the disruption of something new. And while it does take a consolidated effort from the manufacturer and the user for a successful installation (equipment and software), there is a big payoff when a team effort frees up workers to spend time on value-added activities, in a better process flow, with greater productivity and more profitability.