Creating an Industry 4.0 Supply Chain for Sheet Metal Fabricators

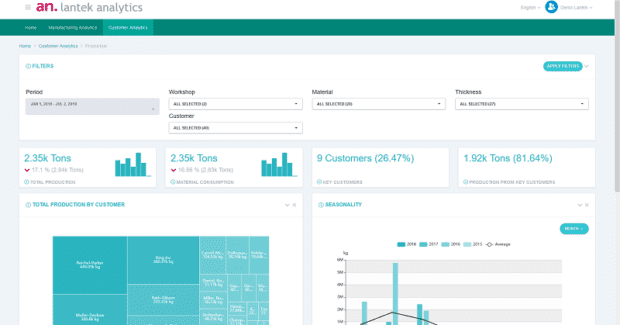

Manufacturers with an existing ERP or sales order processing system can transfer data into and out of cloud-based software from Lantek or expand their system using Lantek software for quotation and CRM capabilities, highly accurate costings, Expert CADCAM intelligence, stock management, documentation and invoicing, and control of multi-site operations.

Posted: January 9, 2019

Sheet metal fabricators are becoming aware of the benefits of digitization and the competitive advantage it can deliver for their business, but implementing Industry 4.0 can seem daunting. Lantek Systems, Inc. (Mason, OH) Lantek 360 suite of practical and relevant cloud-based software applications at an affordable cost that can produce an immediate impact on efficiency and customer satisfaction: Using the MES Manager manufacturing execution system, engineers can upload a bill of materials for the products being manufactured, including parts and sub-assemblies. Parts are then filtered according to material type and thickness, ready for nesting in Expert CAD/CAM software. At this stage, additional parts from other jobs or remanufactured parts can be added to the nest, optimizing material utilization. Within MES Manager, the full sequence of operations required for the manufacture of each part or subassembly is stored, including (for example) laser cutting, punching, bending, assembly and painting.

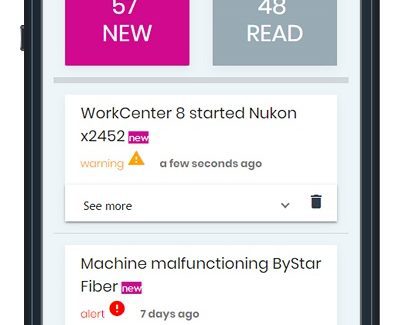

On the shop floor, MES Wos resides on standard touch screen computers or tablets for data capture and to provide operators with details of the sequence of manufacturing operations. Links to the machines record start and finish times for cutting, while employees can log on to jobs and operations for other tasks, recording the progress of each part around the workshop in a paperless environment. Links back to MES Manager make this information available in report form so that managers can see exactly where parts are in the production process in real-time. With this live information, companies can assess and improve the efficiency of their machinery and processes, ensure parts are delivered on time, quickly detect delays and cost overruns and provide customers with accurate information about the progress of their orders.

Manufacturers with an existing ERP or sales order processing system can transfer data into and out of MES Manager, making use of their investment in existing technology. However, companies also have the option of expanding their system with Lantek Integra software that provides wide ranging functionality, including quotation and CRM capabilities, highly accurate costings, use of Expert CADCAM intelligence, as well as stock management, documentation and invoicing, and control of multi-site operations. Taking the first steps towards Industry 4.0 with MES Manager and MES Wos is easy and will deliver traceability and transparency in manufacturing. Areas for improving efficiency become easier to find and test for effectiveness, and customers are kept better informed – making them more loyal. The headache of controlling production becomes a thing of the past.

Using cloud-based applications has clear advantages for sheet metal fabricators: data security and data availability is close to 100 percent with built-in redundancy for backup and recovery, special computing expertise at the fabricator’s site is unnecessary because it is supplied by Lantek and the cloud service provider, data can be accessed from multiple locations for maximum flexibility for multi-plant operations and mobile working, high security levels and encryption prevent data abuse and ensure that only the latest versions of the data are being used, cost of access to high value and complex computer equipment and services is low, software maintenance and updating is managed by Lantek, and additional software modules can be accessed or deactivated as the needs of the company evolve.

Lantek Systems, Inc., 5412 Courseview Drive, Suite 205, Mason, OH 45040-2355, 877-805-1028, www.lanteksms.com.