Hybrid Wheel Plate for Automated Machine Loading

The flexible UtiliTrak VC wheel plate from Bishop-Wisecarver combines low rolling friction with high speed capacity for automated machine loading applications that can make machining operations more efficient.

Posted: January 18, 2019

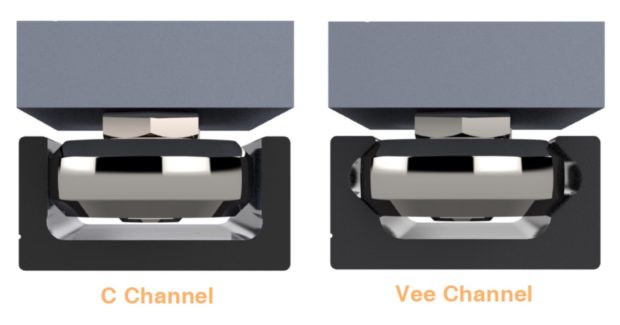

The UtiliTrak® VC (Vee/Crown) wheel plate from Bishop-Wisecarver Corporation® (Pittsburg, CA) is a compact hybrid design of the DualVee® and crown roller wheel that is perfect for automated machine loading and other applications. It seamlessly pairs both the vee and C-channel profiles to fit the specific application: The wheels of the UtiliTrak VC are compatible with both vee and open track channels to help reduce ordering complexity. The VC wheel plate is also dimensionally interchangeable to enable direct replacements and alternatives for existing UtiliTrak wheel plate installations and ensures that parts and accessories work for both versions (wiper caps, felts, brakes, adjustment wrenches, etc.). The hybrid of the vee and crown wheel design also allows for up to two degrees of misalignment.

The VC wheel plate incorporates many of the benefits of DualVee Motion Technology to provide self-cleaning wiping action for use in contaminated environments, as well as smooth and quiet, low friction motion. This wheel plate provides high performance and quality by incorporating proven designs and ensuring the same load capacity and life estimates as existing SW series wheel plates. It also simplifies the customer ordering process by offering one system that works for both vee and open track channels, while also maintaining backwards compatibility with existing UtiliTrak installations for easy direct-field replacements and upgrades.

This flexibility, combined with its ability to perform in contaminated environments, low rolling friction and high speed capacity, provides the optimal system in industrial applications such as equipment manufacturing, where automated machine loading can make cutting operations

more efficient. For example, consider the construction of a material drawer used to streamline material loading of a lathe through factory automation. Sliding material drawers can keep parts continuously queued for machining without compromising worker safety. Due to the need for tolerance to high load capacities, building a slide system with a pair of UtiliTrak VC wheel plates with vee or C-channel allows for weight tolerance upwards of 1,000 lb.

Bishop-Wisecarver Corporation, 2104 Martin Way, Pittsburg, CA 94565, 925-439-8272, sales@bwc.com, www.bwc.com.