Making Robots “Tick” for Your Operations

One robot on its own can make a difference in production efficiency. But many shops are realizing how – although what makes one robot “tick” will most likely vary from another – the use of multiple robots in conjunction with each other and/or peripheral technologies can further improve efficiency and accelerate payback.

Posted: January 2, 2019

The benefits of robots are hard to beat. Typically equipped with six axes per robot, industrial robots provide the versatility needed to perform a plethora of applications. From welding to material handling, from dispensing to material removal, these robots are fast and efficient, improving operational productivity. Manufacturers that understand the cost savings associated with robotic automation realize how robot implementation is a logical next step to production efficiency. In fact, many shops are realizing that higher efficiency robots not only lower production costs, but also help adapt to changing demands, providing a competitive advantage – so much so that the worldwide market for articulated robots is expected to grow at a compound annual growth rate (CAGR) of roughly 9.6 percent over the next five years.1

It’s true: the successful implementation of a single robot can make a significant difference to factory operations. However, manufacturers often find that one robot on its own – especially where welding is concerned – is not adequate to fulfill production needs. With any application, factors like part size, product cycle time, weld repeatability and path accuracy must be considered. Depending on the task, optimizing a robot’s usage may greatly depend on the implementation of additional robots, peripheral technologies and innovative tools, along with proper maintenance to ensure consistent performance. And, by doing so, reaching the designated payback goal is more manageable and maximizing return on investment (ROI) is possible.

ADDITIONAL ROBOTS

While material handling robots are suited to complete tasks such as packing and palletizing, welding robots and paint robots are equipped to fulfill their given purposes. Effectively choosing the right number and types of robots to complete a task is paramount when selecting the proper robotic system for your business. This is especially true for arc welding applications, where adding a second or third robot reduces cycle times and can potentially double or triple welding production with no impact on floor space. The usage of additional robots for arc welding also increases the arc density, optimizing production efficiency. Coordinated motion of multiple robots from one controller has enabled hundreds of shops to use multiple robots within the same workspace without risk of one robot interfering with another. The use of coordinated motion also offers simplicity in programming and flexibility for production processes. Aside from synchronizing multi-robot movement, multiple other servo devices can be programmed to move in sync with each other.

For example, a servo motor positioner holding a workpiece works cooperatively from the same job as the robot with welding torch to enable the welding of complex angles and access to multiple sides of a part. Alternatively, an additional robot arm can serve as a “jigless” positioner, where the robot holds and positions a part for processing by other robots, or two robots can handle a single part. Another common practice for mid- to high-volume welding applications is to combine the use of material handling robots with welding robots, adding greater automation to streamline production. For example, a handling robot can move parts from fixture to fixture – loading or unloading weldments – while a welding robot welds parts at another station. No matter the combination, an increase in robot utilization can help reduce costs over time, justifying the initial investment.

PROGRAMMING OPTIONS

Programming functions are becoming popular add-ons post robot installation, especially when multiple robots have been added to the factory floor. Commonly used with cameras or other sensors to move programs relative to shifting parts, the Relative Job controller software function is a perfect example: it allows robot programs to be “cloned” and moved to other stations or robot cells relative to any user-defined frame or reference. Not only is an effective use of this and many other functions a time-saver, but it can also greatly reduce training time.

If you cannot interrupt production, comprehensive offline programming software, such as MotoSim® or OCTOPUZ®, enable operator training, robot programming and optimization from a desktop computer anywhere in the world. Operators at any size company have the ability to create, test and adjust robot programs before they are implemented on the production floor. This style of programming provides the flexibility needed to maintain a competitive edge in manufacturing today, allowing for a higher mix of jobs with a simple transition from one job to the next. Larger organizations can also reduce programming time and inconsistencies from multiple plants and cells by distributing the program from a central, controlled source.

https://youtu.be/0Ht9tt0qXek

MEASUREMENT TOOLS

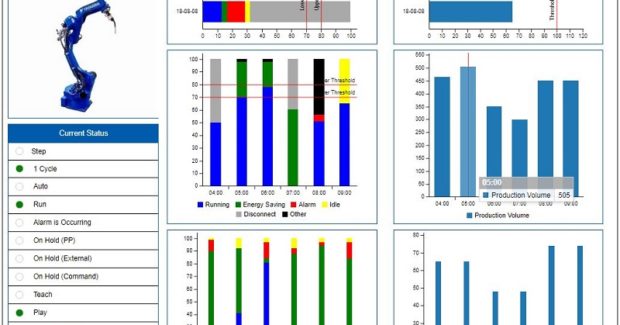

Next-generation robotic automation and manufacturing processes, inspired by Industry 4.0, are fueling a higher level of production efficiency throughout the manufacturing sector by relying on the flow of data. The smart factories that were once in the distant future are now emerging, leveraging concepts such as deep learning for planning, scheduling and predictive maintenance. Finding balance amid the vast combination of robots, sensors and other smart factory tools, however, will be necessary for continued success. Keeping this in mind, decision-makers are realizing a key element to successful robot utilization is tracking Overall Equipment Effectiveness (OEE) throughout a production environment. This is made possible by implementing a systems management and control platform to visualize the status, health and performance of factory devices.

Factory automation management software like Yaskawa Cockpit™ actively monitors, accumulates and visually delivers up-to-the-minute operational and production data through the use of a Standard Open Platform Communication Unified Architecture (OPC-UA) interface. This platform provides a unified controls approach where operational knowledge can be synchronized and shared throughout an extended enterprise, or through external systems via cloud technology.

RETROFIT HARDWARE

Advancements in sophisticated technologies often prompt many shops to make upgrades to robot systems after installation. While new weld torches may be better suited to fulfill unique welding requirements, end-of-arm tooling can change the purpose of a robot completely to meet a new variety of demands. The life cycle of a robot can also be extended through service retrofits and technology upgrades, optimizing performance, reliability, quality and safety. While certain upgrades may have some minimum requirements provided by newer robotic controllers, many of the new technology and sensors can potentially be added to an older generation system to give it the capabilities of a new cutting-edge system.

LIFE CYCLE MANAGEMENT

Maintaining peak robot performance is essential to lasting ROI. Aligning your company with a committed robotic automation partner can help execute the best practices needed to ensure proper equipment maintenance and performance, bolstering product quality, customer satisfaction and corporate growth. From grease analyses to inventory strategy, there is much to consider. Having access to diverse support services with highly skilled technicians for maintenance, troubleshooting and repair can also maximize uptime and accelerate ROI. While having 24/7 access to technical support can be extremely helpful, shops have the ability to do a lot of technical work on their own, thanks to service-specific software and web-based tools:

- Calibration: Well-used robots or drive-related repairs can sometimes lead to miscalibration issues with a robot or tooling. To restore production to peak performance after any repair, it is a good idea to be sure that proper calibration is restored as well. Economical software tools for calibration are available to improve absolute positioning accuracy, Tool Control Point (TCP) and tool posture, giving robot operators the ability to manually tune a robot from the convenience of a laptop computer. Furthermore, to ward off any post-repair calibration hiccups down the road, calibration software should be used in the robot’s ideal operating state so that absolute positioning can be measured and recorded. This way it can be referenced after a mechanical failure to help restore perfect calibration.

- Troubleshooting: Approximately half of industrial downtime can be attributed to the troubleshooting process. Following guided steps from web-based maintenance systems like RobotPro®, most of the information that operators need to service a robot can be gained in a few clicks, saving time and money. User-friendly tools with graphical interfaces such as this empower operators to quickly identify alarm error causes and to tackle repairs with minimal guesswork.

Aside from comprehensive customer and technical support, there are peripheral tools that may aid robot performance. For example, Pendant Armor®, which is often used to prevent damage to a programming pendant, is an energy-absorbing frame designed to protect exposed components most often damaged when the pendant is dropped. This extends the life of a teach pendant by preventing broken buttons and damaged electronics, reducing costly replacements and increasing uptime.

CONCLUSION

With two million manufacturing jobs set to go unfilled due to talent unavailability by 2025, the need for robotic automation intensifies daily.2 Similarly, with product life cycles becoming shorter and more customized, part complexity is greater, solidifying the need for robots on the factory floor. One industrial robot on its own has the potential to make a difference in production efficiency, but now shops are realizing that the use of robots in conjunction with each other and/or peripheral technologies have the potential to further improve efficiency and accelerate ROI. While what makes one robot “tick” will most likely vary from another, the results should be the same: long-term profitable success.

References

- “Global Articulated Robot Market 2018 by Manufacturers, Regions, Type and Application, Forecast to 2023,” Decision Databases, 2018.

- “The Skills Gap in U.S. Manufacturing: 2015 and Beyond,” The Manufacturing Institute and Deloitte, 2015.