Self-Tuning Mass Damper Improves Machined Part Quality, Increases Productivity, Saves Energy

Using the STMD tool holder from MAQ, parts manufacturers, machine tool builders and cutting tool manufacturers can reduce cycle time and cost of ownership by 30 percent, decrease tooling costs by 5-10 percent, cut energy consumption by 2-3 percent and curtail scrap output by 1-2 percent.

Posted: January 17, 2019

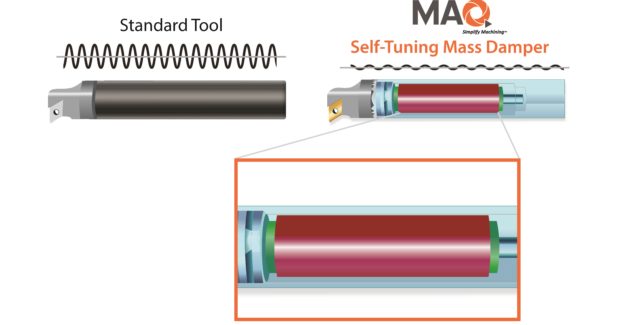

Available in more than a dozen length-diameter combinations, the Self-Tuning Mass Damper™ (STMD) tool holder from MAQ (Stockholm, Sweden) features a tungsten mass inside the tool that can be used by parts manufacturers, machine tool builders and cutting tool manufacturers to reduce cycle time and cost of ownership by 30 percent, decrease tooling costs by five percent to ten percent, cut energy consumption by two percent to three percent, and curtail scrap output by one percent to two percent. “The STMD is totally plug-and-play and maintenance free,” says Dr. Qilin Fu, the chief executive officer and a co-founder of the company. “This technology enables automatic tuning of the mass dampers without using complex mechatronic systems. It also minimizes the need for tooling changes and is a cost-effective alternative to complex de-vibe tools that require manual adjustment. Given the high volume of machining operations, even the smallest percentage reductions can result in substantial savings.”

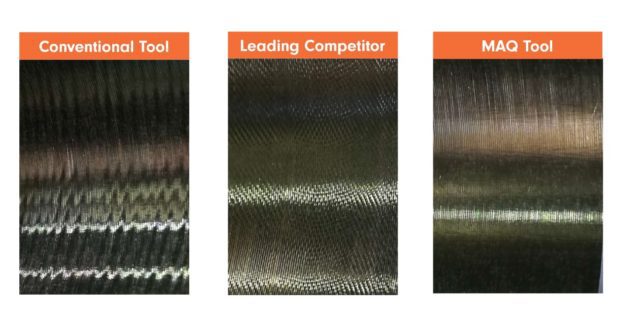

The tungsten mass is supported by special polymer discs that have frequency-dependent stiffness. As cutting forces are applied to the tool, vibration occurs on a frequency band. To counteract such movement, the STMD self-adjusts to that frequency to maximize the mass damping effect. According to tests conducted at a leading machine tool builder in March 2018, the STMD showed significantly less displacement than other tool holders and demonstrated superior versatility with respect to speeds, feeds, depth of cut and L/D ratio. STMD tool holders improve feeds and speeds, decrease adjustment time and promote superior surface finishes that don’t require secondary operations. With STMD, it becomes unnecessary to slow down, reduce depth of cut or otherwise lengthen cycle time.

MAQ, Brinellvägen 68, Stockholm, Sweden 114 28, 724-875-5358 or 46-73-2750-415, francois@maqab.com, www.maqab.com.