Streamlining the Internal Supply Chain for Job Shops

Small and mid-sized make-to-order manufacturers can use KeyedIn Manufacturing 5.06 for ERP to further streamline key business processes, maximize their limited resources and be well-positioned for growth.

Posted: January 9, 2019

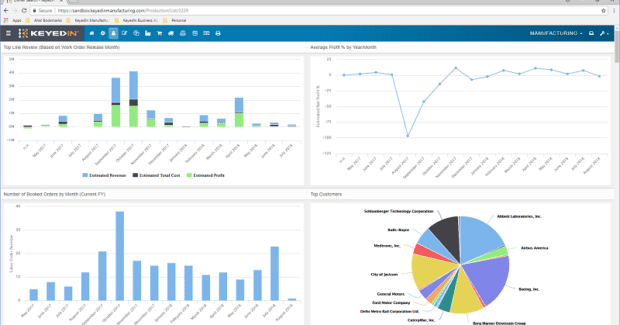

With Microsoft Azure as the hosting infrastructure, cloud-based KeyedIn Manufacturing 5.06 for Enterprise Resource Planning (ERP) from KeyedIn Solutions, Inc. (Bloomington, MN) delivers increased functionality for small and mid-sized make-to-order manufacturers that allows them to further streamline key front-office manufacturing management processes. Using standard role-based dashboards and workbenches, these users now have even more visibility to issues requiring immediate attention. “Custom manufacturers continue to experience strong growth, but what they really need are systems that reduce redundancy and streamline key business processes,” said Dave Lechleitner, the director of product marketing for KeyedIn. “This latest ERP release, combined with Microsoft Azure infrastructure, means shops can maximize their limited resources and be well-positioned for growth.”

“Microsoft Azure allows users to leverage a world-class secure computing environment with the benefits of a true cloud platform,” added Kevin Hurley, the chief technology officer for KeyedIn. “This platform can scale with users and with our software, as well as being aligned with our technology.” KeyedIn Manufacturing 5.06 also features these key enhancements:

- Back flushing material and labor to reduce the cost and effort for managing low cost material or labor.

- Product templates and operation standards to reduce the time to create new estimates or release new work to the shop floor for parts similar (but not the same) as previous work.

- Creation of packing lists from the shop floor application.

- Employee supervisor visibility to employee information from the shop floor application.

KeyedIn Solutions, Inc., 8500 Normandale Lake Boulevard, Suite 400, Bloomington, MN 55437, 952-835-1041, www.keyedinerp.com.