Automated Double-Side Fine Grinding

Using a Twin Loader for automated machine tending, the highly rigid, high precision Peter Wolters AC microLine 1250-F/H from Lapmaster Wolters combines servo-drive technology with in-process load pressure to guarantee high stock removal rates with high precision contactless measurement control.

Posted: February 20, 2019

The highly rigid, high precision Peter Wolters AC microLine® 1250-F/H from Lapmaster Wolters (Mount Prospect, IL) uses Siemens servo-drive technology up to 70 kW, combined with a maximum 4000 daN load pressure in process, to guarantee high stock removal rates. Its revised working wheel cooling labyrinth with increased flow volume helps ensure high precision contactless measurement control. Machine options include:

- Different epicyclic workholder drive systems are available.

- Automatic carrier loading concept with carrier exchange time ≤ 60 seconds.

- Software functions such as constant removal rate or automatic working wheel wear compensation.

- RangeCare® (remote maintenance system via mobile communications or VPN).

- DataCare® (integrated process data recording)

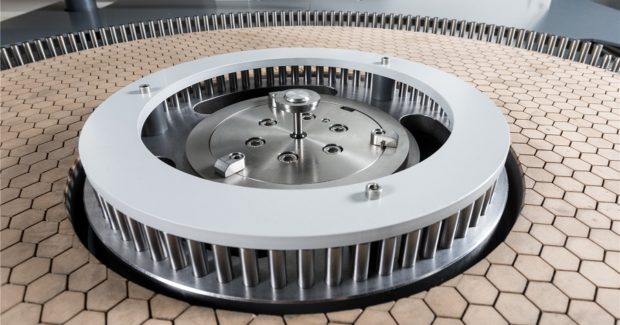

Combined with a Twin Loader, the AC microLine 1250-F is a powerful production system consisting of the grinding machine and automation for automatic workpiece carrier exchange. The core of the Twin Loader is a rotary index table, which is used as a buffer to reduced auxiliary process times and optimize utilization of machine capacity. The operator can unload finished parts and prepare workpiece carrier loading with unmachined parts parallel to the ongoing grinding process. Simultaneously loading and unloading of two workpiece carriers into-and-from the machine via Twin Loader significantly reduces the exchange time and drastically increases overall system productivity, with exchange times of 60 seconds for six workpiece carriers ranking among the best in the market. For even higher efficiency, the modular Twin Loader can be complemented with a robot cell for workpiece carrier loading and unloading.

The Twin Loader uses solid steel weld construction instead of aluminum profile frames, a linear electrical unit for workpiece carrier loading and unloading, improved accessibility through a new frame design, a flexible selectable position for the machine operator and/or robot cell for optimum adaptation to the user’s conditions, along with faster rotary table positioning via servo drive. For optimal integration in existing or new production lines, the robot cell is equipped with a SCARA robot for pick-and-place for workpiece loading and unloading and an infeed conveyor for unmachined part feeding, along with an outfeed conveyor for removing finished parts. This cell can directly load and unload AC microLine machines. After grinding cycle ends, the upper machine part swivels out, providing the SCARA robot with optimum access to the grinding area, allowing workpiece carrier loading and unloading to start. Finished part removal and subsequent loading with an unmachined part is alternated for an efficient loading and unloading time.

The robot cell can also be combined with a Twin Loader for a significant increase in productivity and optimization. Workpiece carrier loading and unloading takes place in the Twin Loader during the processing cycle of the AC microLine machine to reduce auxiliary processing times to a minimum.

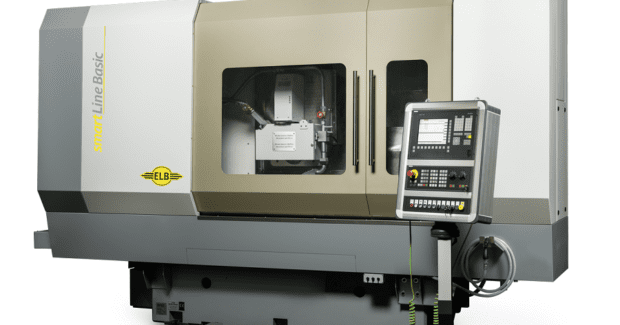

Lapmaster Wolters also offers the Elb-Schliff smartLine modular grinding machine that covers the entire spectrum of traveling table grinding systems, from simple reciprocation surface grinding through speed-stroke, slot and profile grinding all the way to creep-feed grinding. The versatile building-block system of this machine allows almost any combination of components to be configured to solve a specific grinding task. With the smartLine grinding machine, workpieces with grinding lengths of 600 mm to 2,000 mm, widths of 400 mm to 750 mm and heights of 500 mm to 1,250 mm can be machined. Users can select main spindles ranging from 5.5 kWh to 60 kWh. The machine base and column are made of high quality and environmentally-friendly manufactured Microgranite, which guarantees optimal damping properties – especially critical for grinding processes – increased rigidity and high thermal stability that cannot be achieved with any other material.

The modular configuration of the machine series enables a variety of special grinding tasks to be fulfilled for shops that must meet a wide range of requirements, such as automotive suppliers, tool manufacturers, aerospace manufacturers or other applications. The smartLine machine enables high precision grinding of parts with a high level of long-term precision. Decades of experience in the production of grinding machines from are reflected in the quality of the grinding parts and the very high level of customer satisfaction.

Lapmaster Wolters, 501 West Algonquin Road, Mount Prospect, IL 60056, 224-659-7101, www.lapmaster-wolters.com.