Consider the Big Picture When Manufacturing Complex Tube Assemblies

Fit-up, fixturing and assembly of multiple tubes can be difficult when coping, mitering and other secondary operations are required after bending. This is where new tube fabrication technology shines. Though it may bill out at a higher machine rate/hour, the time, material, tooling and labor it saves delivers a lower cost per assembly – and higher profitability.

Posted: February 12, 2019

Tube fabricators are continually looking for ways to eliminate waste in their manufacturing process and save cost. This becomes even more evident when multiple tubes are required to build an assembly, where one of the most cumbersome challenges is the joining of tube components: fit-up, fixturing and assembly difficulties are often encountered, especially when coping, mitering and other secondary operations are required after bending. For example, consider a high-end fitness equipment manufacturer who develops a new aerobic product known as the STEP. This complex assembly is comprised of nine stainless steel tubes varying in length, one main tube and eight individual sections. It requires coped tube ends to be welded to the side of a common bent tube. The plant is equipped with both older technology, which offers a lower machine rate/hour, as well as state-of-the art tube processing equipment. The manufacturer needs to determine the most cost-effective method to produce the STEP.

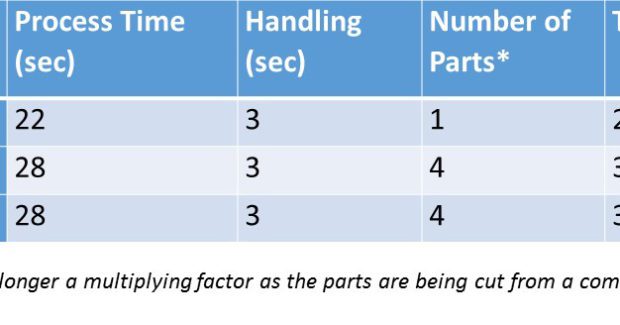

If the older equipment is used, the manufacturer will process nine tubes individually to their specified geometries. Total bending time is about three minutes. After each tube is bent, each part must be positioned in a complex fixture for the coped milling and miter saw processes. As shown in Table 1, coping and sawing the nine parts takes approximately 4.4 minutes. To optimize fit-up requires a fixture of higher complexity which, in turn, increases fixture costs. Although the machine cost per hour is lower, this approach increases labor time and material consumption, and likely results in a higher cost per produced assembly.

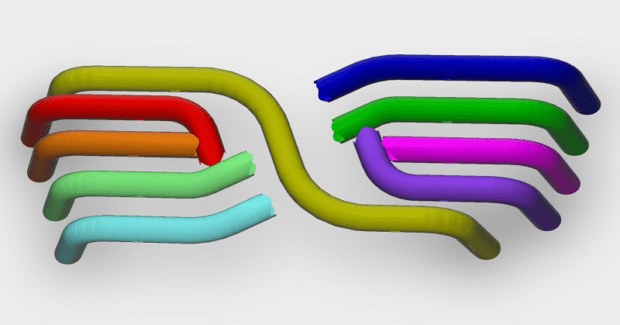

If the parts are produced on the newer machines, the process can be simplified and accomplished more efficiently, starting with a laser tube system – which is the most effective solution for coping. The assembly CAD model is imported into the laser tube programming software, where it is broken down individually into each of the nine tubes to identify the cut features for each. The assembling software then creates a nest based upon the combination of tubes (Figure 1). The complex assembly in our example is optimized from nine to three sticks of material. Using a couple of mouse clicks, the programmer can quickly optimize the assembly with the addition of tabs, slots, and micro-tabs to simplify the assembly process and minimize fixturing requirements (Figure 1-1).

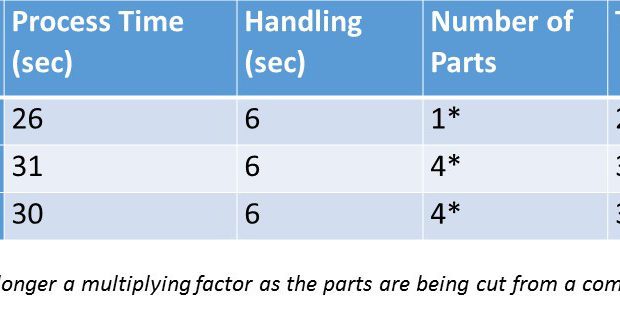

Before cutting, variables like stretch and spring-back must be considered as part of the coping and bending operations. To identify these factors using newer technology with older equipment, a program is generated at the bending machine that incorporates a shallow, medium, and deep bend from a sample stick of the stainless steel at a known length. The bent sample is then measured to identify how much spring-back and stretch occur during the forming process. If part tolerances are critical, the evaluation should be performed each time the material batch changes to accurately understand compensation requirements. This data is stored for use by both the laser tube and bender software programs. The laser tube operator then incorporates these stretch and spring-back characteristics into the cutting program, which will automatically compensate for these factors and ensure that each tube is cut to the appropriate length. The material is now ready to be cut into the three lengths, requiring 1.5 minutes. When compared to the coping and sawing process, the productivity increase is about 3X faster.

From cutting, the tubes go to the bending process, which is most effectively achieved with an all-electric, multi-axis tube bending system with CNC control. The original CAD model is imported into the tube bending programming software and the compensation data is merged with the program. Remember that there are nine parts to be processed, but now only three sticks of material. By sequencing the bend programs, the parts will be produced sequentially, yielding all of the components needed for the STEP assembly. The cycle time to process the three tubes is 1.6 minutes, doubling the productivity. With minimal effort, the micro-tabs between each component can be broken to individualize them and prepare for the next manufacturing phase.

So overall, the entire processing time is reduced from 7.4 minutes to just over 3 minutes, not accounting for the time required for material handling and fixturing. Even if the new equipment bills out at a much higher machine rate/hour, the time, material and labor saved will deliver a lower cost per assembly.

When determining the best way to manufacture complex tube assemblies, consider the big picture and what the overall impact will be. An older machine with a lower rate cost per hour may achieve short-term savings, but in the long-term the total manufacturing costs will be higher. Advancements in machine tools, CNC control and offline CAD/CAM software capabilities allow manufacturers to have greater process control, improved productivity and material utilization – which, in turn, boosts profitability.