Cost Effective Robots for Part Inspection, Pick and Place

The KMXL Cartesian multi-axis robot from Hiwin is quickly and easily configured for high accuracy and repeatability in specific pick and place or part inspection applications.

Posted: February 2, 2019

Quickly and easily configured for specific pick and place or part inspection applications, the compact KMXL Cartesian multi-axis robot from Hiwin Corporation (Huntley, IL) is an integrated, cost effective system of standard KK Series robot components built with high strength steel for high rigidity and driven by precision ballscrews that allow each robot to have high accuracy and repeatability. The nut of each ballscrew is integrated with its sliding carriage for a compact design. Each carriage slides efficiently and smoothly on recirculating bearings. AC servo motors ranging from 50W to 1 kW drive each axis of the robot. The wattage required for typical system applications is usually less than 750W. Each servo motor has the option of 13 bit or 17 bit resolution, with 17 bit resolution providing a resolution of 131,072 counts/rev. The rated speed of most of the servo motor line is 3,000 rpm with a maximum no-load speed up to 4,500 rpm. Each servo motor has the option to be equipped with an electro-mechanical brake, which may be required for many vertical applications to prevent back driving.

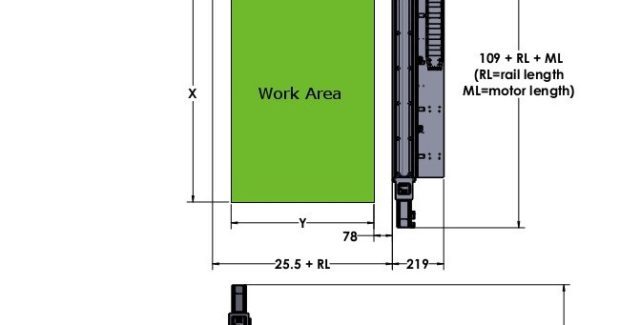

The KMXL Cartesian system is the largest size offered in Hiwin standard systems, allowing for longer reach in the Y-axis while carrying larger loads to reduce the need for gantry configurations. It provides the largest work area capacity of all their standard systems. The Z-axis of this configuration uses a size KK86 that allows for faster speeds with heavier loads in the Z-direction. The KMXL configuration consists of the following KK robots for each axis:

- X-axis uses a KK100 with a 20 mm ballscrew running a rail length from 980 mm to 1,380 mm at precision speeds of 1,120 mm/sec to 440 mm/sec and normal speeds of 800 mm/sec to 530 mm/sec. Precision repeatability of ±0.005 mm and normal repeatability of ±0.01 mm.

- Y-axis and Z-axis use a KK86 with either a 10 mm ballscrew running a rail length from 340 mm to 940 mm at precision speeds of 740 mm/sec to 610 mm/sec and normal speeds of 520 mm/sec to 430 mm/sec, or a 20 mm ballscrew running a rail length from 340 mm to 940 mm at precision speeds of 1,480 mm/sec to 1,220 mm/sec and normal speeds of 1,050 mm/sec to 870 mm/sec. Precision repeatability of ±0.003 mm and normal repeatability of ±0.01 mm.

For help determining the correct system for your application, please contact Hiwin engineering.

Hiwin Corporation, 12455 Jim Dhamer Drive, Huntley, IL 60142, 847-827-2270, Fax: 847-827-2291, info@hiwin.com, www.hiwin.com.