Doing Tasks with Robots That Were Not Possible Before

The intuitive Force Guide integrated force control system from Epson Robots enables robots to perform grinding, polishing, part insertion, screw driving and other high precision operations that require high performance motion guidance.

Posted: February 1, 2019

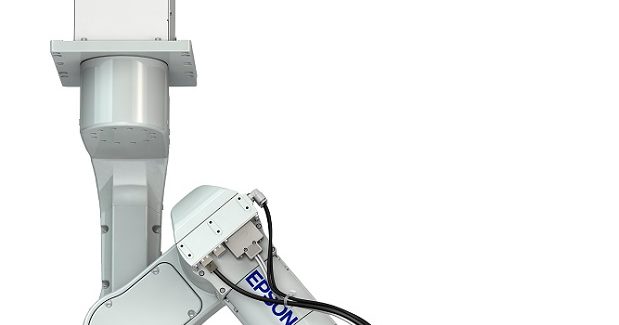

The Force Guide integrated force guidance system from Epson® Robots (Carson, CA) takes high performance robot automation to the next level with amazing precision and outstanding rigidity. Force Guide is a tightly integrated force control system that allows robots to sense and make precision moves using force feedback data. Powered by proprietary Epson Quartz Technology, it enables robots to detect six axes of force with precision down to 0.1 N. Driven by real-time servo system integration, Force Guide delivers fast, tactile feedback to guide robots for high-precision parts placement. Designed for easy configuration and set up, this system is fully integrated into the Epson RC+® development environment and features an easy-to-use point-and-click interface with graphical wizards, charts, pre-configured solutions and built-in decision-based flowcharts and intelligent objects that reduce the amount of coding and development time for applications requiring high precision. It is perfect for tasks such as part insertion, screw driving, grinding/polishing and more.

“This is a revolutionary force control system that is opening up possibilities for robot automation in areas that were not possible before,” said Gregg Brunnick, the director of product management for Epson Robots. “It enables robots to tackle applications with high precision or high performance motion guidance requirements, making it a great fit for a wide range of high precision applications.” Force Guide features real-time monitoring and data logging of force feedback for quality control with a multi-axis force/torque sensor that includes three linear and three rotational measurement axes.

Epson also offers their Synthis™ T6 All-in-One SCARA robot as a perfect way to automate factories without wasting time or money on expensive, complex, slide-based systems. Available at the low price of $9,495, this innovative alternative installs in minutes and virtually eliminates any space-constraint issues. The T6 is ideal for simple applications such as pick and place, assembly, parts handling and dispensing applications. Its All-in-One design features a built-in controller (conveniently housed in the robot base) and power for end-of-arm tooling that runs at 110V or 220V and requires no encoder battery, minimizing factory downtime for maintenance and reducing overall cost of ownership. The T6 handles payloads up to 6 kg with a reach to 600 mm and the ability to handle multiple tools. It includes integrated vision options designed specifically for robot guidance, as well as fieldbus interface solutions, Epson RC+ 7.0 API software for open-platform functionality, teach pendants, and customizable GUIs.

Epson America, Inc., 1650 East Glenn Curtiss Street, Carson, CA 90746, 562-290-5910, Fax: 562-290-5999, epson.com.