Double-Cut Carbide Burrs Increase Stock Removal in Stainless Steel, Steel, Cast Steel and Composites

For less changeovers on demanding production runs, Norton Double-Cut Carbide Burrs from Saint-Gobain Abrasives are ideal for efficiently removing surface stock and weld splatter, deburring and chamfering, and medium to light cleaning applications.

Posted: February 22, 2019

The new line of Norton Carbide Burrs from Saint-Gobain Abrasives (Worcester, MA) is designed for surface removal on demanding production runs with less changeovers. The hardness of a tungsten carbide substrate, stronger tooth formulation due to a decreased tooth wedge angle, and numerous cutting edges all provide these new carbide burrs with a significantly extended life and better stock removal performance. “They can be used longer with fewer changeovers on challenging production applications, as to compared to other double-cut burrs,” said Patrick Carroll, a senior product manager at Norton | Saint-Gobain Abrasives. “Operators will achieve high stock removal and smaller, granular chip-break on hard-to-grind workpieces.” Norton Double-Cut Carbide Burrs are ideal for efficiently removing surface stock and weld splatter, deburring and chamfering applications, along with medium to light cleaning. Specially-designed tool geometries are ideally suited to meet the growing demands for stainless steel, steel, cast steel and composites applications.

These versatile new carbide burrs perform well at higher temperatures and can be used longer than high-speed steel tools. They can be used on handheld tools, such as the Norton Pneumatic Die Grinder, or on automated CNC machines. The Norton Carbide Burr line includes 30 different tools and is offered in seven types: SA Cylindrical without End Cut, SB Cylindrical with End Cut, SC Ball-Nosed Cylindrical, SD Ball Shape, SF Ball-Nosed Tree, SG Tree with Taper, and SL Ball-Nosed Cone style. A kit is also available, including the most popular five burr types for smaller job requirements. The Norton Pneumatic Die Grinder quickly and comfortably accomplishes a wide range of portable grinding applications without the need to change machines. “This versatile die grinder will enhance the performance of numerous abrasive products, including mounted points, flap wheels, traditional specialties such as cartridge rolls, and our carbide burrs,” added Carroll.

Operators will immediately notice a reduction in vibration attributed to the grinder’s double-bearing spindle, resulting in longer tool life and finer finishes. Precision is as simple as adjusting the speed regulator, giving the operator complete control of the surface finish needed to complete the job. An ergonomic and streamlined non-slip grip achieves better tool handling, increased comfort and reduced grinding fatigue. This grind is small and light weight for additional control, with the ability to get into small features in parts. It has a free speed of 25,000 rpm to make quick work of deburring, light-to-medium surface cleaning and stock removal applications, welding preparation, and finishing in metal fabrication, MRO, foundry, shipbuilding, aviation, and automotive applications.

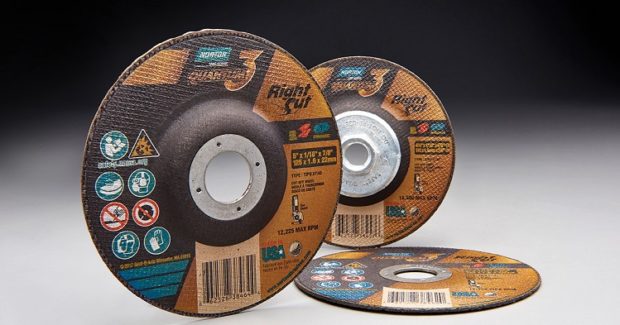

Saint-Gobain Abrasives also offers Norton QUANTUM3™ RightCut Wheels that boast a more rounded grain for faster cutting action with less vibration that is instrumental in reducing operator fatigue when cutting metal all day. When working on thinner materials or, in the case where operators need to get the job done quickly, the 0.045 in NQ3 RightCut wheel is ideal. Due to its proprietary grain, this wheel easily cuts through the workpiece quickly, increasing efficiency and saving time. “The bond system of NQ3 technology allows for better mix control during the manufacturing process. This keeps the individual grains from clumping together for a more even wear of the cut-off wheel,” explained Alicia Castagna, PhD, the product manager of thin wheels at Norton |Saint-Gobain Abrasives. This is also true with the 1/16 in NQ3 RightCut wheels when cutting thicker materials. Longer life translates to more productivity, keeping the operator working smarter, not harder.

The Norton Quantum3 line of RightCut wheels are offered in four Type 01/41 and three Type 27/42 cutting application SKUs. All wheels are currently in stock and are available in 4½ in, 5 in and 6 in sizes that are made in the U.S. To request a product test, please click here.

Norton | Saint-Gobain Abrasives, 1 New Bond Street, Worcester, MA 01606-2614, 508-795-5000, www.nortonabrasives.com.