Flap Discs Provide Superior Stock Removal, Surface Finish and Service Life on Steel and Stainless Steel

The composite backing on POLIFAN PSF Z-TRIM flap discs from PFERD can be trimmed to extend service life and reduce time-consuming disc changes when surface grinding, weld grinding, blending, chamfering, and deburring steel and stainless steel.

Posted: February 22, 2019

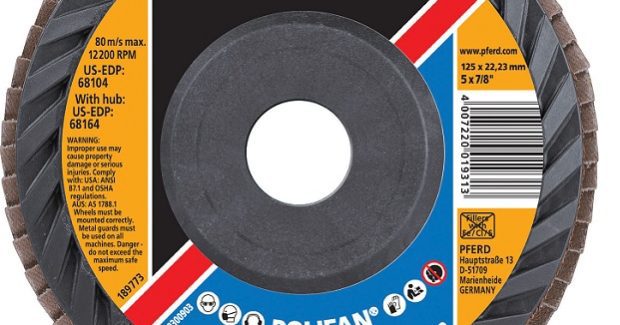

The versatile POLIFAN® PSF Z-TRIM universal flap disc from PFERD Inc. (Milwaukee, WI) have a lightweight composite backing that can be trimmed to extend service life and reduce time consuming disc changes. The composite backer and flap arrangement help reduce vibration and noise levels. Produced with a higher density of zirconia-coated material (zirconia alumina Z) than standard PSF flap discs, these discs provide long service life, an improved surface finish, and a soft, cushioned, contamination-free grinding effect in applications ranging from surface grinding, weld grinding, blending, chamfering, and deburring on steel and stainless steel. Their premium zirconia self-sharpening abrasive grain produces high stock removal rates throughout the life of the disc, along with a long service life. The high-density flap arrangement, with an increased amount of coated material vs. conventional flap arrangement, also facilitates reduced vibration and noise levels, along with flexible grinding action and superior results on irregular shapes.

POLIFAN PSF Z-TRIM flap discs perform on all power outputs, though high-powered angle grinders will achieve optimal results. They are available in 4½ in and 5 in diameter sizes, with either a 7/8 in plain arbor hole or a 5/8-11 thread for threaded spindles, in grit sizes of 40, 60, and 80. The 5/8-11 thread quick-change version is made with a zinc hub.

PFERD also offers their patented COMBICLICK® quick-change fiber disc system that provides lower workpiece temperature while improving both stock removal and disc life. Designed for use with coated abrasive, non-woven and felt discs, this system consists of a specially-developed backing pad with an innovative locking mechanism. The threaded backing pad allows the discs to be used on most available angle grinders. The special geometry of the cooling slots ensures a high throughput of air that significantly reduces the thermal load on the abrasive material and workpiece. This optimized cooling, together with the quick-mounting system, rugged fixture, and secure attachment of the disc, allow COMBICLICK to provide up to 30 percent lower workpiece temperature, up to 25 percent increased stock removal, and up to 30 percent longer disc life. The extensive range of these fiber discs provides the optimal product for any grinding application.

These fiber discs come in various grit sizes, abrasives, and diameters of 4 in, 4½ in, 5 in and 7 in, depending on the disc type. Applications include working on weld seams, deburring of steel components, rough grinding, fine grinding of stainless steel components, removal of mill and casting skins, and working on narrow, hard-to-reach areas, such as cooling ribs. Varieties of COMBICLICK discs include fiber discs available in ceramic (CO) and aluminum oxide (AO), zirconia alumina (Z), silicon carbide (SiC), and COOL versions with active additives to prevent loading reducing heat build-up; non-woven unitized discs in hard through soft types for use in face-down grinding on variable speed angle grinders; and felt discs for pre-polishing and high-gloss polishing. COMBICLICK backing pads permit the use of these discs on all common angle grinders. Plus, the patented mounting system minimizes disc changing time. The backing pads also come in 4 in, 4½ in, 5 in and 7 in sizes (like the discs).

COMBICLICK kits offer a convenient way to get started with the system. A wide variety of coated and non-woven materials are included to test performance and surface finish results to help determine the ideal product selections for the customer’s applications prior to bulk purchases. The included discs provide solutions for rough grinding, fine grinding, surface conditioning, pre-polish and polishing to a mirror finish.

PFERD Inc., 9201 West Heather Avenue, Milwaukee, WI 53224, 800-342-9015, www.pferdusa.com.