Larger, Stronger and Safe Mobile Robots for Leaner Production

The powerful, robust MiR500 mobile robot from Mobile Industrial Robots autonomously picks up, transports and unloads heavy loads and can be equipped with pallet forks, conveyors, a robot arm or other options to support a wide range of applications.

Posted: February 2, 2019

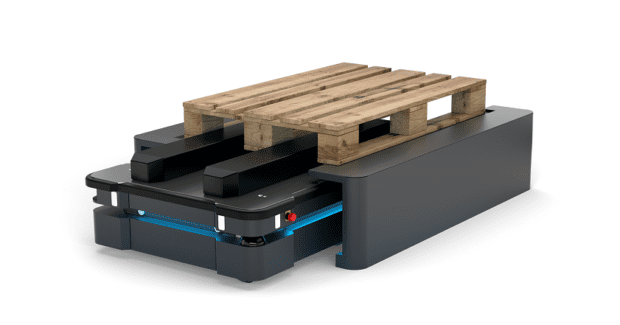

The MiR500 mobile robot from Mobile Industrial Robots Inc. (Holbrook, NY) optimizes the transport of heavy items and pallets, with two flexible pallet lifts for the two most commonly used types of pallets: the EU pallet and the 40 in x 48 in pallet. This robot has a lifting capacity of 500 kg (1,102 lb) and can automatically collect, transport and deliver pallets. It incorporates innovative safety features and uses advanced technology and sophisticated software to recognize obstacles in a 360 deg radius and navigate autonomously via the most efficient route to its destination, even in dynamic environments where people and vehicles are moving. “To compete today, manufacturers must be more customized and flexible than ever before, including how they transport materials between production cells,” said Thomas Visti, the chief executive officer of MiR. “These mobile robots are ideal for that task, helping innovative shops take their automation initiatives to even higher levels.”

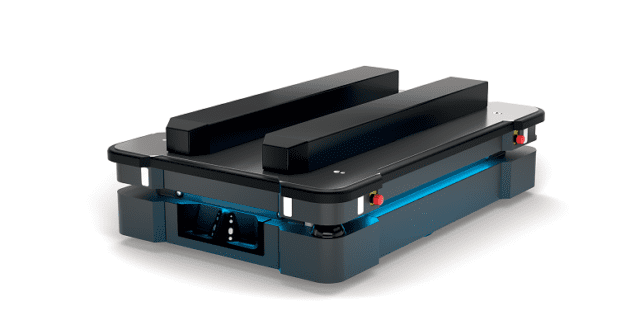

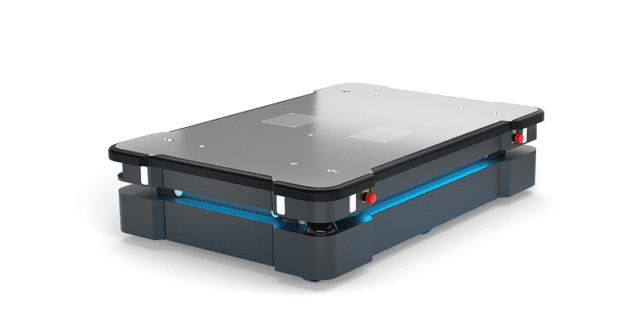

The powerful and robust MiR500 automates the transportation of pallets and heavy loads up to 500 kg with a footprint of 1,350 mm x 920 mm. It safely and efficiently maneuvers around people and physical obstacles. When it meets obstacles, it automatically re-routes to avoid costly lags in logistics processes. Equipped with the latest laser scanning technology, this robot delivers a 360 deg visual for optimal safety using 3D cameras with a range of 30 mm to 2,000 mm above floor level to detect pallets. With the MiR500 Pallet Lift, the robot picks up, transports and unloads pallets autonomously, freeing up employees for more valuable tasks. There is no need to change the facility layout when operating the MiR500 because the function of wires, magnets or QR codes is replaced by sophisticated navigation software. Simply download CAD files of the facility into the robot or use its laser scanners to create a map – that’s all it takes to ensure a fast and cost-efficient implementation.

The rugged MiR500 robot is compliant with ISO/EN 13849 and fulfills the EMC requirement for industrial and light industrial use. Its robust exterior can withstand dropped cargo and easily navigate up and down ramps and even through shallow water puddles. The user-friendly robot is controlled with the intuitive MiR Robot Interface via smartphone, tablet or PC and can be programmed without any prior experience. The robot can also be integrated into an ERP system for a fully automated operation. With the ability to quickly and easily integrate different top modules, the MiR500 can be equipped with pallet forks, conveyors, a robot arm or other options to support a wide range of applications.

Mobile Industrial Robots Inc., 1340-2 Lincoln Avenue, Holbrook, NY 11741, 631-675-1838, emu@mir-robots.com, www.mobile-industrial-robots.com.