The Day the Robots Take Control: Part Two

Is the robot revolution really such a bad thing? As automation and robotics sweep through manufacturing, Smart Factories driven by digital information are slowly emerging as an ultra-lean answer to the skilled labor shortage and other competitive issues.

Posted: February 15, 2019

Continuing the discussion that began in Part One, the skilled labor shortage, combined with increasingly adaptive, affordable and often superior capabilities in automation and robotics, is pushing the metalworking business toward an inflection point in advanced technologies, a period of disruption where manufacturers must respond effectively or face competitive deterioration – and they are definitely responding. For more evidence of how the robotic revolution is sweeping through the metalworking industry, take a look at some of the latest innovations that have recently been introduced:

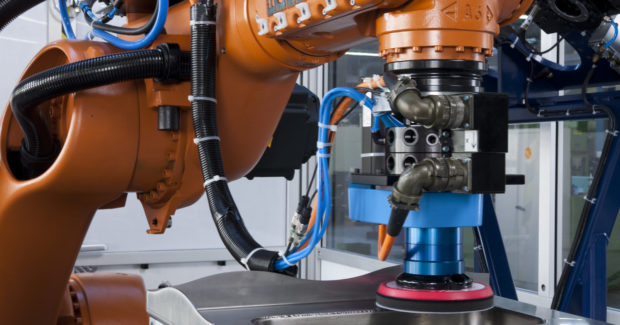

Robotic Operations that were Previously Not Suitable for Automation

From automotive manufacturing to stainless steel machining to drilling and tapping and more, this versatile quick tool change system from Suhner enables robots to drill, grind, file, cut and deburr in demanding, high performance applications.

Cost Effective Robots for Part Inspection, Pick and Place

The KMXL Cartesian multi-axis robot from Hiwin is quickly and easily configured for high accuracy and repeatability in specific pick and place or part inspection applications.

Robot Automation of High-Mix/Low Volume Part Production

To automate the high-mix/low volume operations needed by job shops to compete effectively, Hurco uses fully automated robot systems coordinated by a centralized job management system to connect CNC machining centers with collaborative robots, multi-axis serial robots and pallet systems.

Easy and Intuitive Error-Free Robotic Programming

Robotmaster V7 software from Hypertherm makes the task-based programming of automatic integrated welding, contour trimming, cutting, dispensing, deburring, drilling and fastening easy and intuitive, even for first-time robot users with no expertise.

Automation Apps Increase Reliability in Smart Factory Production

Individually configurable software application packages from Liebherr can increase the control and reliability of robotic production in an Industry 4.0 operating environment.

Larger, Stronger and Safe Mobile Robots for Leaner Production

The powerful, robust MiR500 mobile robot from Mobile Industrial Robots autonomously picks up, transports and unloads heavy loads and can be equipped with pallet forks, conveyors, a robot arm or other options to support a wide range of applications.

Intuitive Cobot Automates Repetitive Tasks

The advanced TM Series Collaborative Robot from Omron boosts production and reduces employee fatigue by safely automating most repetitive production tasks, such as machine tending, loading and unloading, assembly, screw driving, gluing, testing or soldering.

Change End-Of-Arm Tooling on Cobots in Seconds

With the lightweight Quick Changer from OnRobot, any operator can change the end-of-arm tooling on collaborative robots in a few seconds with just a click.

Plug-and-Play End-of-Arm Vacuum Tooling for Cobots Improves Productivity

The flexible piCOBOT end-of-arm-tool from Piab is designed for maximum flexibility and reach with 3.8 in to 5.6 in wide, ±15 deg tiltable gripper arms that can be fitted with two suction cups. Alternatively, the gripper can be replaced by a single suction cup mount directly on the cobot’s pump unit.

Tool Room Cobot

The Cora cobot from Zoller improves tool room economics by automatically picking, assembling, adjusting, clamping, measuring, cleaning, marking and labeling tools in full support of all standard tasks for tool preparation.

Robotic Inspection of Weld Defects

Easily interfaced to any robot system or welding machine, the i-FACT intelligent robotic inspection system from Servo-Robot automatically digitizes joint and bead surfaces to provide geometric data and detect weld defects.

Integrated Robotic Automation of Machine Tools and Assembly

For machine shops that need multi-spindle, high precision machining centers, SW North America can also integrate automated robot cells, assembly systems and turnkey production systems for increased productivity.

Robotic Air-Cooled MIG Guns

TOUGH GUN TA3 Robotic Air-Cooled MIG Guns from Tregaskiss now include configurations for additional through-arm style FANUC, KUKA and Yaskawa Motoman robots.

Fast and Easy Robot Cell Configuration and Deployment

Application Builder from Universal Robots walks users through the entire process of building a successful machine tending, assembly or packaging application with step-by-step guidance on end effectors, programming, machine interfaces and more that is optimized for throughput and cost.

Robotic Mobile Bending Cell

The automated Mobile Bending Cell from Bystronic can process large lots, or bend small lots or individual parts manually when necessary. Just plug in and start bending.