How to Make Hydraulic Ironworkers More Efficient and User Friendly

Low-profile LED work lights, a jog motor control and a snap ring removal tool from Scotchman can greatly increase productivity in punch, shear and notch station operations.

Posted: March 6, 2019

Three new options now available for current hydraulic ironworker models from Scotchman Industries, Inc. (Philip, SD) make them more efficient and user friendly. These features include:

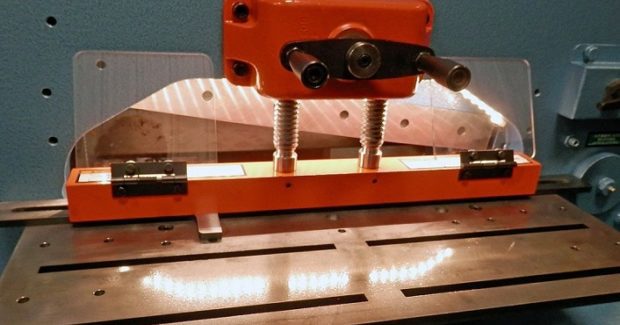

1. New low-profile LED work lights provide more visibility when operating the ironworker

These work lights are currently factory installed. Optional retrofit kits are available for in-field retrofitting to existing Scotchman ironworkers. Available on all current models located in the following workstations:

- PF45: located on the punch station.

- 5014-ET: located on the punch and shear station.

- 50514-EC: located on the punch, shear, and notch stations.

- 6509, 9012,12012, all Dual Operator (DO) models and F185: Located on the punch and shear stations.

- ShearMaster: Located in the shear station.

2. Jog motor control for 50 ton ironworkers

Increase precision when setting the stroke control on the 50 ton ironworker by adding this jog motor control, which is especially helpful in aligning and positioning tools accurately and while doing regular machine maintenance.

3. Snap ring removal tool for #20 punches

This tool makes an otherwise tedious task fast and easy. Sold separately or included with the purchase of a #20 punch and die package.

Scotchman Industries, Inc., 180 East Hwy 14, PO Box 850, Philip, SD 57567, 800-843-8844, Fax: 800-843-5545, info@scotchman.com, www.scotchman.com.