Keeping an Eye on Every Weld Seam

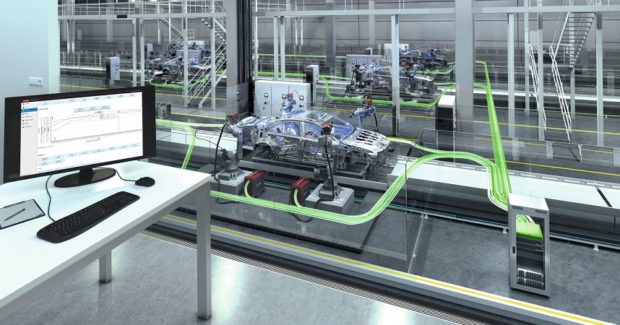

Automated data collection software from Fronius records welding data for customized process documentation and analysis that increases welding productivity, process feedback and transparency, and product safety.

Posted: March 13, 2019

Recording welding data for documentation and analysis is becoming increasingly important for fabrication shops of all sizes. Documenting production data ensures the transparency and traceability of individual steps in the production process, which contributes towards consistent quality in production and helps minimize risks. Managing data digitally also saves time and money, as handwritten notes become a thing of the past and an analysis can be generated at the touch of a button. A digital data management tool for welding technology helps users keep an eye on each individual weld seam as well as the overall system status, allowing errors to be detected. The Light, Basic, and Premium versions of the WeldCube data documentation system from Fronius USA LLC (Portage, IN) deliver all these benefits.

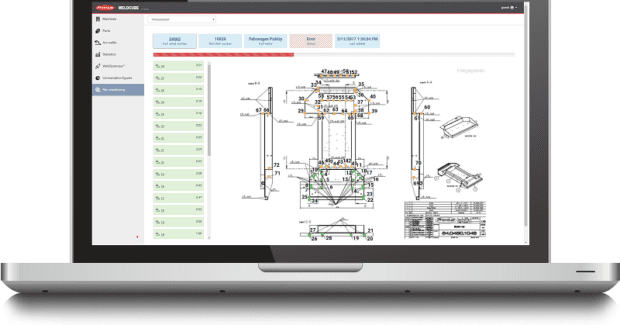

Light is the beginners’ version that gathers decentralized data for each welding system, enabling traceability at weld seam level. This web-based feature conforms to EN 1090 and is contained in the SmartManager of every TPS/i power source and can be used free of charge. The system records the time, duration, current, voltage, wire speed, and power for each weld seam and stores the mean value. Users can export this information as a pdf file. The parameters of jobs can also be viewed and compared. Basic is the ideal system for smaller shops that use only a limited number of welding systems. The software records decentralized, precise actual values at a sampling rate of up to 100 ms to monitor limits on each welding task. Users define parameter limit values and the system informs them if these are undershot or exceeded. Parts that may not conform to the required quality standards can be checked and rejected immediately.

As with Light, Basic data are recorded on the welding system itself for viewing online for each TPS/i. The user can create or edit jobs in the tool, transfer them to other devices using the import and export function, and save time. All data can be exported as pdf or csv files. Premium saves welding data from multiple systems in a central database with intelligent management, statistics, and analysis functions. Saving data from networked systems centralizes data for documentation related to each component, with separate pdf reports generated per component. Premium monitors the progress of a component and provides details on every weld seam. The software uses a traffic light system to show in real-time whether a seam has already been welded and whether any limit values were violated. The system prepares data analyses in table or graph form at the touch of a button. With the help of intelligent filters, users can create and share their own statistics. They can also customize the user interface to meet their needs. Prepared data can be sent to third-party systems using the file export feature and a web API interface.

Fronius USA LLC, 6797 Fronius Drive, Portage, IN 46368, 219-734-5701, welch.stephanie@fronius.com, www.fronius.com.