Metal Cutting Showcase

Take a closer look at some of the latest advances in metal cutting equipment that might help you increase productivity, improve quality and reduce costs.

Posted: March 22, 2019

For metal cutting equipment supplier profiles, please click here.

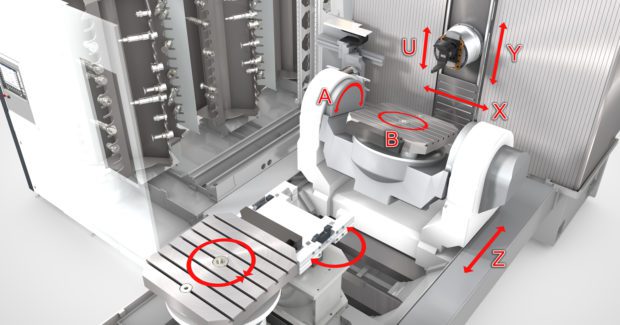

Ultimate One-and-Done Multi-Axis Machining

To increase the profitability of machining fluid ends, gate valves, drill bits and pump housings used in oil and gas applications, the Heckert DBF 630 six-axis machining center from Starrag turns, mills, bores, drills and threads complete parts in one set-up.

Program Conversationally, But Cut Like a Boss

ChipBoss CAM software from Milltronics lets conversational program users take advantage of the latest trochoidal machining strategies to reduce cycle times up as 50 percent with 3X to 5X better tool life.

Y-Axis Horizontal Turning Center for Tough-to-Machine Materials

For unprecedented rigidity and accuracy, active thermal compensation in the high productivity PUMA 2600 SY II from Doosan Machine decreases deformation up to 70 percent and a built-in spindle minimizes vibration with better acceleration and a smooth, fast ramp-up.

Flexible Goes Adaptive in FMS

Next-generation flexible manufacturing systems from Fastems fulfill the growing needs of shops to handle shorter product lifecycles, higher product mixes and lower volumes.

Extreme Positioning Flexibility for Machining Complex Parts in a Single Setup

The highly versatile UMC-750P machining center from Haas quickly positions parts to nearly any angle for 5-sided (3+2) machining, full simultaneous 5-axis motion for contouring and complex machining, or more traditional tombstone machining like a HMC.

Machine Highly Complex Geometries with Fewer Setups and Less Operations

For large parts weighing up to 880 lb, the versatile a500Z 5-axis horizontal machining center from Makino maximizes both metal removal rates and perishable tool life through unparalleled system rigidity.

Next Generation Honing of Engine Blocks, Liners and Parts

The SV-30 cylinder hone from Sunnen features automatic step-and-repeat capability for in-line and V-block engine configurations that produces ideal bore roundness and surface finish in a variety of part types and materials at an affordable price.