Precision Shot Peening of Helicopter Rotor Shafts

This custom extended-height Peen-Rite RSSA-6 precision shot peening cell from Guyson was delivered in less than 20 weeks to process critical helicopter main gear box rotor shafts.

Posted: March 11, 2019

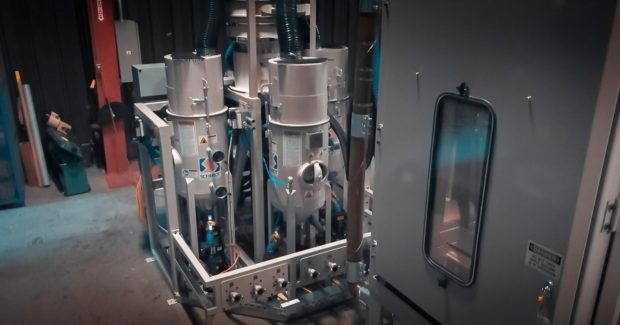

The Guyson Corporation of U.S.A. (Saratoga Springs, NY) recently completed a custom extended-height Peen-Rite RSSA-6 cell for precision shot peening of critical helicopter main gear box rotor shafts. This system complies with AMS 2430 and is capable of bar-code scanning alpha numeric part numbers contained in the customer’s routing. Its compact Logix L24 can store and recall over 1,000 recipes. A precision-machined table and slide base provide accuracy for the 80 in traverse used in shot peening the shaft FD and OD to consistently repeatable 8-10A Almen Strip intensities. The user opted for a standard dual media arrangement consisting of three 3.5 cu ft pressure vessels, a precision 75/12 cyclone and programmable quick-connect media hoses. Nine Thompson grit value combinations precisely control the media delivery, which is monitored and displayed on a Panel View 700. This fully custom cell was completed in less than 20 weeks.

Guyson also designed and built an automated tire mold cleaning system that features a precision nozzle manipulator with three axes of movement. This custom pressure-blast machine is engineered to quickly and non-destructively clean both two-piece and segmented molds. Its roof-mounted nozzle motion system directs the blast from four pressure nozzles that are rigidly bracketed in position on the wrist of the programmable manipulator. The horizontal and vertical range of nozzle motion accommodates molds of various diameters and tread widths, while the third axis precisely controls the pitch or angle of impingement of the blast stream to facilitate rapid and thorough cleaning of details of target surfaces. This system uses exclusive Metalbead® media that consists of microscope spheres for cleaning hard-to-reach areas in complex dies and molds. This media is soft so that it resists fracture and leaves molds or dies damage-free.

The Guyson Corporation of U.S.A., W.J. Grande Industrial Park 9090, 13 Grande Boulevard, Saratoga Springs, NY 12866, 518-587-7894, Fax: 518-587-7840, www.guyson.com.