Cut Faster, Last Longer When Turning the Most Challenging Materials

TS2000 and TS2500 grades for heat-resistant alloys from Seco Tools boost surface quality on machined parts and provide a more consistent tool life while machining heat resistant materials, superalloys and titanium alloys used in aerospace, power generation and biomedical engineering.

Posted: April 25, 2019

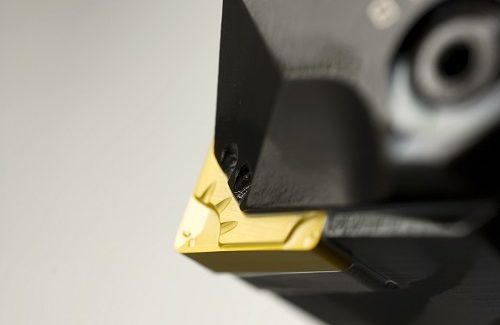

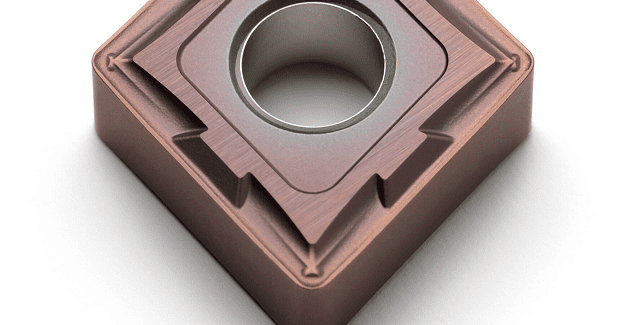

TS2000 and TS2500 are a new generation of grades for heat-resistant alloys from Seco Tools, LLC (Troy, MI) that employ a new edge preparation process and new coating to cut faster, work harder and last longer when turning even the most challenging materials. A new edge preparation process gives the grades a better edge integrity and an improved adhesion between substrate and coating. This boosts surface quality on machined parts and gives the insert a more consistent tool life while machining heat resistant materials, such as superalloys and titanium alloys commonly used in the aerospace, power generation and biomedical engineering industries. TS2000 is the hardest of the new grades. It incorporates a new special PVD coating that provides excellent wear resistance and offers improved reliability. The coating is thicker than present coatings and reduces the risk of plastic deformation as well as crater wear. TS2000 is aimed at high-quality finishing of heat-resistant alloys, but with the strength to handle semi-roughing situations as well.

TS2500 is especially designed to handle interrupted cuts, tough cast skin and higher stress. It is the ideal grade for roughing and semi-finishing applications in various kinds of super and titanium alloys. For a complete system, Jetstream Tooling® technology is also available to dramatically improve chip control and feed and speed capabilities. It works by delivering a high-pressure jet of coolant directly to the optimal position near the cutting edge/cut zone. It quickly and efficiently removes heat from the cutting zone and hardens chips for fast, easy removal.

Other grades for turning challenging materials include wear-resistant TH1000 and TH1500 turning insert grades. With its reliable edge toughness and high chip resistance qualities available across a broader product range, the TH1000 TiSiN-TiAlN nano-laminate PVD-coated grade enables shops to productively tackle a wider variety of ISO H5-H10 applications. This grade maintains long tool life when machining hardened steels – from 50 HRC to 62 HRC – hard surfaced components and complements the TS2000 and CP200 carbide grades and CBN170 grade to form a complete finish machining package for superalloy materials. TH1000 excels in finishing operations and performing interrupted cuts in hardened steels. With respect to machining superalloys such as Inconel 718, Waspaloy and Nimonic C263, this grade brings fast cutting speeds to continuous finishing and semi-finishing operations. Furthermore, the latest TH1000 chipbreaker inserts bring optimum chip control and high process security to a broader working range.

The TH1500 grade is perfect for processing hardened steels from 40 HRC to 55 HRC and, through its product expansion, allows shops to excel in an increased number of ISO H10-H15 applications that require high cutting data and continuous-cut operations. TH1500 also provides superior finish turning of grey and ductile cast irons in applications with low-to-moderate cutting speeds. Furthermore, because of its advanced grade profile, which includes an α-based Al2O3 CVD coating, Ti (C,N) middle layer and a super fine grain substrate, TH1500 makes a great alternative to CBN and ceramic cutting tools in situations that involve machining hardened steel workpieces in unstable conditions. Because of its superior finish turning capabilities in grey and ductile cast iron, TH1500 complements the TK1001 and TK2001 grades.

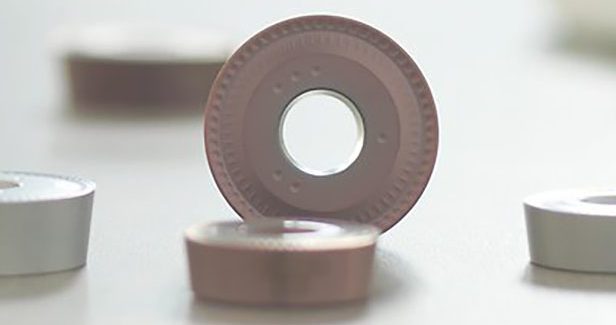

For shops that struggle to manage metalworking chips and optimize tool life in extreme turning applications, Seco -R3 and -RR93 insert geometries make easy work of such challenging jobs, such as turning railway car wheels. These inserts combine roughing and medium finishing chipbreakers with Duratomic® grade technology. The -RR93 chipbreaker boosts tool life, improves productivity, increases product reliability, enhances chip management and generates a superior surface finish. This design replaces the -RR94 geometry. For medium finishing applications in steels, difficult stainless steels and super alloys, the -R3 geometry offers optimally positioned grooves that control chips even at depths of cut as small as 0.059 in (1.5 mm), at high feed rates from 0.024 in/rev to 0.047 in/rev (0.6 mm/rev to 1.2 mm/rev) and at cutting speeds from 3.543 ipm to 6.299 ipm (90 m/min to 160 m/min). Within these cutting-data ranges, the correct choices depend on the application at hand. The -R3 geometry replaces the previous -R2 geometry.

To produce smoother finishes that are ideal for the surface areas of railway wheels, as well as for medium roughing applications with difficult materials, RCMT20-R3 positive screw-clamped additions to the range reduce machining vibration significantly. Dedicated insert edge treatments and retained functional toughness arrest comb cracks and increase edge security. The new RCMX and RCMT geometries feature the Duratomic CVD aluminum-oxide coating process that optimizes mechanical and thermal properties for enhanced performance. This technology also provides used edge detection to reduce insert cutting-edge waste. The new -RR93 and -R3 geometries and Duratomic grades have been tested in most common railway wheel materials, including R7, R8, R9, M1, Class B and Class C. Range Overview:

- -RR93: 9 inserts (RCMX20, RCMX25, RCMX32).

- -R3: 10 inserts (RCMX20, RCMX25, RCMX32, RCMT20).

- All inserts available in new Duratomic TP grades.

- RCMT20-R3 is available in TS grades TS2000 and TS2050.

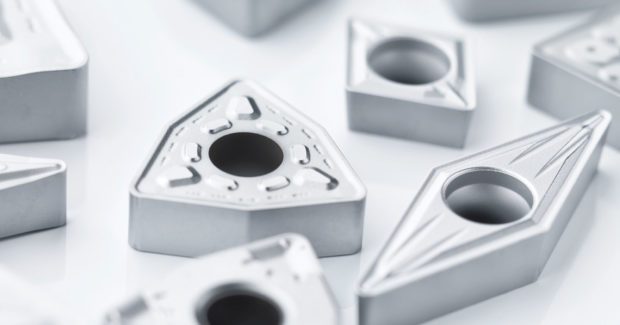

Seco also offers TP3501, TP2501, TP1501 and TP0501 grades with Duratomic technology and Chrome Used-Edge Detection that excel in steel turning applications. These grades incorporate Edge Intelligence that integrates extensive high-performance insert experience and knowledge with Chrome Used-Edge Detection that allows a user to instantly identify when an insert edge has been used, making every edge count and reducing potential waste. TP3501 provides optimal application security in steel turning applications that involve numerous interrupted cuts, less stable machines, short time in cut or weak setups due to part size or shape. TP2501 is ideal for reliable steel turning applications, TP1501 is optimized for low-alloy steels and TP0501 is the first choice for productivity in high carbon steels. Each grade offers a comprehensive range that includes hundreds of inserts in a wide variety of available geometries and chipbreakers.

https://youtu.be/x6YwB48QRAc

Seco Tools, LLC, 2805 Bellingham Drive, Troy, MI 48083, 248-528-5451, www.secotools.com.