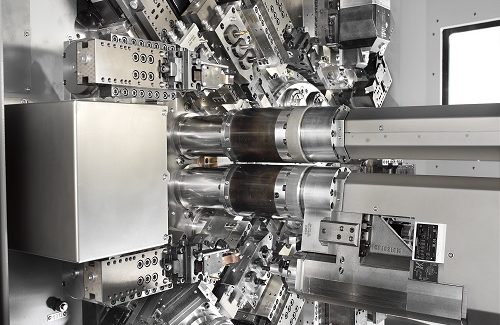

Multiple Machining Processes Complete Complex Parts in One Operation

The MS40-8 multi-spindle automatic lathe from INDEX performs off-center drilling, thread cutting, inclined drilling, cross drilling, contour milling, hobbing, bevel gear cutting, multi-edge turning and more to completely process even very complex automotive, fastener, connector and aerospace parts in one setup.

Posted: April 15, 2019

Ideal for high volume, precision work in the automotive, fastener, connector, and aerospace industries, the MS40-8 multi-spindle automatic lathe from INDEX Corporation (Noblesville, IN) has eight CNC spindles, two back-working spindles for rear-end machining, and deploys up to 18 CNC slides (X and Z) and additional Y-axes if required. This lathe handles bar stock through an MBL40-8 bar loader or chuck parts. The 110 mm chuck allows machining of pre-formed, forged or extruded parts of up to 80 mm. For simple parts, the machine can be used as a double four-spindle machine, reducing cycle times in half. The heart of the MS40C-8 multi-spindle automatic lathe is its compact spindle drum with eight fluid-cooled motorized spindles with synchronized technology (max 7,000 rpm; 24 kW; 57 Nm). They are characterized by infinitely-variable speed control, high torque, low size and no maintenance requirements.

With the increased number of main spindles and tool carriers, the MS40C-8 is able to completely machine even very complex parts in one operation. Up to two pivoting synchronized spindles are each able to work on up to seven rear end machining tools: four of them can be live. A new feature is that two rear-end machining tools can work simultaneously on the workpiece. A significant highlight of this lathe is its versatile economic usability, including for simple workpieces. For example, if components need to be cut with only a small number of tools, it can be used as a highly productive double four-spindle machine. If the user makes this choice, they have practically two four-spindle machines available with each providing a synchronized spindle for rear end machining. Each cycle finally outputs two finish-machined components from the machine. Since each spindle is independently programmable, it is possible to machine troublesome materials that up to now were hardly suitable for multi-spindle machines. Speed changes are possible also during drum indexing, resulting in no additional downtime.

Because users can set up live tools on the compound slides, multiple machining operations can be accomplished, including off-center drilling, thread cutting, inclined drilling, cross drilling, contour milling, hobbing, bevel gear cutting, and multi-edge turning and more. To maintain high productivity in all of these operations, users can connect to iXworld, an online portal of expanded service offerings from INDEX, for a single interface into a broad spectrum of information and functionality that includes four distinct areas: iX4.0, iXplore, iXshop and iXservices. This suite of services provides them with fast, secure connectivity, production data, remote diagnostics, spare parts ordering from the machine and more, all designed to minimize downtime and further boost machine utilization rates. With iX4.0, they have remote and automated monitoring and reporting of machines that have been equipped with a genubox, a dedicated piece of hardware that provides highly secure remote access via an encrypted online connection.

All INDEX machines sold since 2016 include a genubox and all machines sold since 2007 can be upgraded with one. Through iX4.0, users can conduct usage analysis, set automatic notifications for specific conditions that occur, monitor machine data such as vibrations and temperature, and incorporate predictive maintenance to maximize machine uptime. With iXplore, they have easy and intuitive access to a variety of relevant information: technical information, training schedules, tools for collaborating between customers and applications engineers, and user group forums for networking and discussion with peers. With iXservices, they can identify spare parts, track fault reports, calculate cycle times and receive real-time support from engineers. This function provides a comprehensive overview of the machine and its components, simplifying problem solving in the event of an issue. This can include the use of data glasses and teleservice for an engineer to virtually engage with a machine operator and provide assistance with troubleshooting or maintenance.

With iXshop, users can order spare parts, request services and track the status and history of orders. This function can also be configured to connect with a customer’s ERP for simplified procurement and logistics management. “The iXworld suite of services ensures that our users are equipped for future success,” said Tom Clark, the president and chief executive officer of INDEX. “Manufacturers need more than just the ability to collect data. They must be able to efficiently sort, access and analyze it. With iXworld, we are streamlining that process and we will continue to add to and build upon the platform.”

INDEX Corporation, 14700 North Pointe Boulevard, Noblesville, IN 46060, 317-770-6300, info@indextraub.com, www.indextraub.com.