Next Generation Spindle Alignment for Lathes, Turning Centers

Remarkably easy to use, extremely fast and highly accurate, compact and versatile L-702 and L-702SP spindle alignment lasers from Hamar Lasers reduce tooling costs, scrap rates and downtime to increase throughput, cut costs and boost productivity.

Posted: April 25, 2019

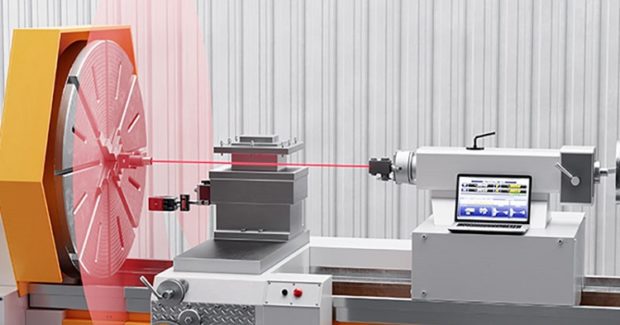

Two spindle alignment lasers from Hamar Laser Instruments, Inc. (Danbury, CT) ensure highly accurate and fast alignment of lathes, turning centers and other machinery: The L-702 spindle alignment laser is a straight-line laser for spindle alignments in lathes, turning centers, OD grinders, slant-bed lathes and transfer-line and rotary-dial machines. The L-702SP spindle alignment laser with scan plane adds a perpendicular scan plane to the L-702 spindle laser beam for checking cross-slide, turret axis squareness and other milling axes in multi-axis, mill-turn machines. “We wanted to add a compact squareness-checking capability to our spindle lasers, so we redesigned our field-tested L-700 spindle laser and brought out the L-702 and L-702SP spindle lasers,” noted Rod Hamar, the president of Hamar Laser. “These spindle lasers help users reduce tooling costs and scrap rates while reducing downtime to increase throughput. Remarkably easy to use and highly accurate, they are up to 70 percent faster than conventional methods.”

Checking and adjusting machine alignment with the new lasers is easy and fast. The L-702 and L-702SP are inserted into spindle chucks and aligned to the spindle’s rotation axis using a T-261 4-Axis Target, then the lathe-bed straightness and parallelism to the headstock are checked. Add in the L-702SP perpendicular scan plane and a A-1519-2.4ZB Wireless Target and the cross-slide, turret or milling axes can be checked for squareness or parallelism. The data is sent to Lathe9 Software for recording and analysis with a very high measurement resolution of .000001 in (0.00025 mm). The L-702SP can also be used to check machine-bed guideway flatness/leveling with the addition of a magnetic base fixture.

Hamar Laser Instruments, Inc., 5 Ye Olde Road, Danbury, CT 06810, 800-826-6185, Fax: 203-730-4611, www.hamarlaser.com.