Robotic Welding Peripheral and Accessory Maintenance

Preventive maintenance on peripherals such as reamers with anti-spatter sprayers and wire cutters is part of the routine care of a weld cell. The time and cost to maintain them properly is small compared to the improvements they provide to the bottom line through higher weld quality, minimal rework and improved productivity.

Posted: April 16, 2019

From reamers or nozzle cleaning stations to wire cutters and anti-spatter sprayers, welding peripherals and accessories can contribute significantly to the success of a robotic welding operation. Besides improving weld quality, they can also help shops maintain high levels of productivity. Reamers in particular are most prevalent in automotive manufacturing, where uptime and quality are critical. This peripheral cleans the welding consumables – such as welding nozzles and gas diffusers – free of spatter, and most automotive welding operations rely on this process after virtually every weld cycle. Other industries, such as heavy equipment manufacturing, also employ reamers and other peripherals in their robotic welding operations, as do some general manufacturers. It’s not by chance that peripherals work the way they do. Like any equipment, caring for them with routine preventive maintenance (PM) is important to gaining optimal performance and longevity.

PM TIPS FOR REAMERS AND ACCESSORIES

A reamer requires regular attention because it operates frequently during the weld cycles. It’s job is important because it performs essential welding nozzle cleaning that helps keep the robotic welding cell up and running and quality on par. Along with PM for this equipment comes PM for its associated accessories: the lubricator, cutter blades and anti-spatter sprayer. Each of these require varying levels of daily, weekly, monthly or yearly PM activities. In addition to inspecting the consumables for wear and replacing as needed, follow this PM routine on a daily basis:

- Check that the consumables are aligned properly to the reamer. This helps ensure that the jaws of the reamer clamp the nozzle to the V-block correctly and that the consumables are lined up concentric and parallel to the cutter blade for optimal spatter cleaning.

- Clean the spindle cover shroud free of spatter and also clean the clamp jaw and V-block surfaces to gain proper nozzle alignment. Use a brush or compressed air. Look for any signs of wear on these components.

- Make sure the air lines connected to the reamer are free of frays, as leaks will prevent the reamer from receiving enough air to remove spatter properly. Look for any damage to the interface cable.

- Check the oil level in the lubricator reserve – the reamer motor depends on a consistent supply of oil. Also check the level of anti-spatter liquid in the anti-spatter sprayer. Fill as needed. An option to simplify PM of the anti-spatter sprayer is to employ a multi-feed system that allows 5 gal or 55 gal drums of anti-spatter liquid to be connected to a manifold system to feed multiple sprayers on multiple reamers. This eliminates the need for daily reservoir fills.

On a weekly basis, continue to examine the integrity of the consumables and follow these guidelines:

- Inspect the cutter blades for dullness, clogging and possible breakage, replacing as necessary. Note the service life of cutter blades will vary based on the application.

- Again, check that the lubricator is working properly with the right level of oil, and clean or replace the filter as needed.

- Check the LEDs to ensure reamer and controller communication, and wipe the nozzle detect proximity sensors clean so they can function properly.

- Look over the spray head on the anti-spatter sprayer to be sure it is delivering a normal amount of liquid spray. Clean the head and adjust as necessary.

Monthly PM for reamers and accessories requires less steps but is more intensive. It may require scheduling a time off cycle to complete:

- Check that the belt tension lock screw and bolt are securely tightened.

- Examine the spindle unit for wear, replacing if necessary, and inspect the solenoids, spooling them to prevent leaks and to make sure they are operating properly.

Lastly, on an annual basis:

- Inspect the drive belt for signs of fraying and replace as necessary.

- Replace the spindle cap seal and repair any visible damage.

- Perform a complete cleanup of the reamer and anti-spatter sprayer.

Though it may seem time-consuming to implement these PM measures, they can typically be completed during routine pauses in production. More intensive activities can be scheduled to prevent interruption to production. Ultimately, PM is time well spent and can help protect the investment in the reamer and its accessories.

PM TIPS FOR WIRE CUTTERS

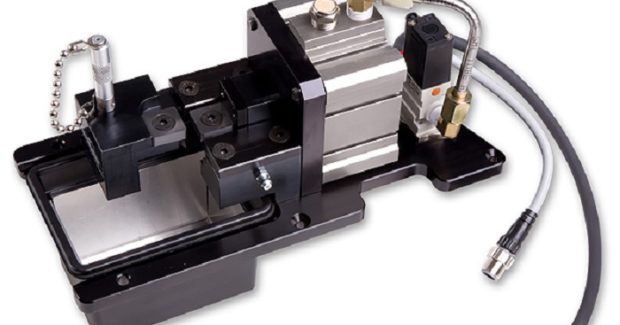

Wire cutters are increasingly being used in automotive and other manufacturing operations. This equipment is integrated into a reamer configuration and used in conjunction with a wire brake on the robotic MIG gun. The wire brake prevents the welding wire from moving, while the wire cutter cuts it at a set distance. This allows for a consistent wire stickout so the robot can touch-sense and track the joint before welding. The results are more accurate weld placement and smooth arc starting. PM for wire cutters is relatively simple:

- On a daily basis, check the airlines and interface cable for leaks or frays. Be sure that the solenoid valve is providing air to the system.

- Weekly, check that the cutter blades are sharp enough to cut the wire. Look for signs of dullness, looseness or breaks. Replace as needed. Also, empty the wire catcher basket.

- Quarterly, apply general purpose grease (NLGI Grade 1-1) through the grease fittings on the sides of the main body of the wire cutter. This helps lubricate the sliding surfaces of the equipment.

THE VALUE OF PERIPHERALS

Peripherals such as reamers with anti-spatter sprayers and wire cutters can help shops realize a greater return on their investment in a robotic welding system. They aid in high weld quality, minimize rework and help meet productivity goals. Train welding operators to follow recommended PM activities as a part of a routine care of the weld cell. The time and cost to care for them properly will be small in comparison to the improvements that they can provide to the bottom line.