Automated Monitoring of First Piece Inspection on the Shop Floor

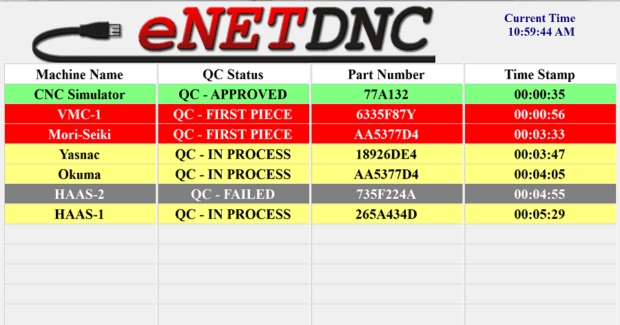

Working in conjunction with eNET Machine Monitoring, the eNET QC Status Dashboard from eNETDNC is locally-hosted software that increases visibility and accountability throughout the quality control operation for the first-piece inspection process.

Posted: May 31, 2019

The latest piece of the shop floor puzzle is ready to be put into place. The eNET QC Status Dashboard from eNETDNC (Greenfield, WI) is locally-hosted software that works in conjunction with eNET Machine Monitoring to increase visibility and accountability throughout the quality control operation for the first-piece inspection process. Made in the U.S., this customizable dashboard was created, tested and perfected through a close partnership with users of eNET Machine Monitoring and is fully interactable on any touch-screen. It is designed for a large-screen display in the QC department and, if desired, the QC manager can also display a seat of this dashboard on their desk computer for increased department visibility. When QC First Piece is scanned at a machine, the job is immediately time-stamped and blinks on-off on the dashboard to catch the attention of any available QC inspector. The job remains in QC First Piece status until an inspector interacts with the dashboard and changes job status to QC In Process.

An automated email or text notification can be sent to the QC manager from the eNET Machine Monitoring software if a machine remains in QC First Piece status for a predetermined length of time. Once the first-piece inspection is completed, an inspector simply changes the status on the dashboard to QC Approved or QC Failed. The software can also be setup to keep a machine waiting on a first piece inspection locked in setup-mode until its job status is changed to QC Approved. Once an inspector changes job status to QC Approved, all of the live eNET Machine Monitoring dashboards also change to match the job status so that the operator knows he can begin running production for that job. The first cycle run by the machine after a QC Approved status change automatically puts that job into “production” mode in the software and causes that job to be removed from the eNET QC Status Dashboard.

For more information, look at other advances in part inspection and also subscribe to F&M.

eNETDNC, 4702 South 47th Street, Greenfield, WI 53220, 414-817-7070, Fax: 414-817-8386, luke@enetdnc.com, www.enetdnc.com.