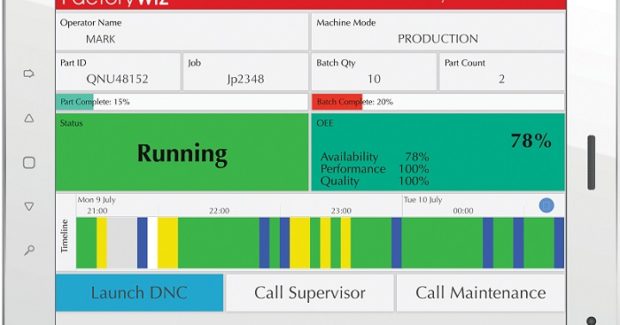

Flexible Tablet Interface for Easy Exchange of Shop Floor Information

For CNC machine tool and non-CNC asset monitoring and data collection, the Flexible Tablet Interface from FactoryWiz uses a live display dashboard to drive behavior and see quantifiable improvement in shop productivity.

Posted: May 31, 2019

FactoryWiz (San Jose, CA) offers the Flexible Tablet Interface (FTI) for their powerful, web-based Monitoring System that is used for CNC machine tool and non-CNC asset monitoring and data collection. FactoryWiz Monitoring uses live display dashboards to drive behavior and see quantifiable improvement in shop productivity. It can back-feed an ERP system with actual metrics based on computerized, non-judgmental data. This complete on-premise intranet system includes software to drive all large screen dashboards and automatically e-mail historical reports with real-time status of manufacturing assets and process. With the FTI, system owners can now use customized widgets for data entry and display without programming knowledge. The FTI also allows them to easily customize their Tablet Interface for their specific application, creating a custom Machine Operator Tablet with a standardized company look-and-feel.

While all collected data is valuable, meaningful display data is subjective and different for almost everyone. The primary function of this Operator Tablet is for bidirectional exchange of information, such as On Pace/Off Pace production status, light maintenance reminders, interaction with the Quality department and, most importantly, as a tool for operators to input downtime “why” reasons that are defined by management and displayed as large buttons for operators to easily access. Reasons for machines not in production can include critical information, including No-Material, 1st Article Inspection, Program Change, Down for Maintenance, etc.

For more information, look at other advances in the smart factory and also subscribe to F&M.

FactoryWiz, 6920 Santa Teresa Boulevard, Suite 201, San Jose, CA 95119, 408-224-9167, Fax: 408-224-9168, www.factorywiz.com/monitoring.