Show Me the Money: Costing and Quoting in the Metal Fabrication Industry

Few factors have a bigger impact on the sales, health, and bottom line of your business than costing and quoting. Most of us realize that if we set our prices too high then our products and services will not sell, but the problem is often the opposite: we price too low. How do we set prices?

Posted: May 29, 2019

The film Jerry Maguire made popular the phrase, “Show me the money!” The metal fabrication industry is a long way from the world of high-profile sports agents, but the same principle applies: you need to see the money. And that means we need to think well about the prices we quote. Few factors have a bigger impact on the sales, health, and bottom line of your business than costing and quoting. Most of us realize that if we set our prices too high then our products and services will not sell. But the problem is too often the opposite: we price too low. (Some reports suggest that 80 percent of pricing in the metal fabrication business is too low!) It’s easy to panic when our quotes that we sent do not always produce orders. How do we set prices?

1. WE NEED TO KNOW THE PART COST

Correct pricing begins with knowledge – and the first thing we must know is the actual cost of the parts produced. In metal fabrication, that means the cost of materials, machines, and manpower. Figure 1 shows typical CAD/CAM software costing. Notice that the software calculates the cost of the material used (in this case titanium) based on the raw material cost and the amount of material used. The material used can be either the actual material needed to make the part (the True Shape Material Cost) or the amount of material used by the smallest rectangle that the part will fit in (the Rectangular Shape Material Cost). By knowing both costs, the Estimator can quickly determine a least cost and a most cost range. Notice that the software also provides an Operating Costs. This calculation can include the cost to operate the machine, the cost of consumables, the shop overhead costs, and even the cost of the operator’s time.

2. WE NEED TO KNOW THE NESTED COST

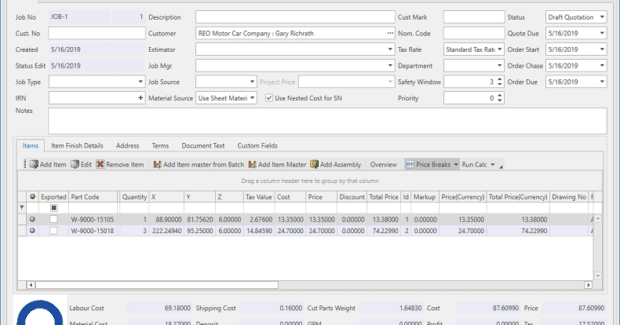

Part cost alone is often insufficient to make an accurate quote, however. For that, the estimator needs to know the nested cost: the cost of the part as it sits on the material that is cut. Nested cost accounts for the extra material that is lost to scrap around the part. In Figure 2, you see that the cost of the part (when considering the nest) is $13.35 rather than $13.16. This is a more accurate and complete picture of the cost of making this part.

SUMMARY

In a future discussion we can address other costing and quoting issues. But for now, let’s summarize four important points to remember:

- Too often fabricators price their work too low.

- The first key to accurate quoting is knowledge.

- We need to know the part cost and the nested cost to begin to think accurately quote orders.

- CAD/CAM software improves the accuracy of quoting by providing critical cost information.