Do More, Spend Less

Trying to find ways to cut more in a single setup without having to purchase new machines? These rotary tables can provide an affordable way to increase the productivity of your vertical machining centers.

Posted: June 11, 2019

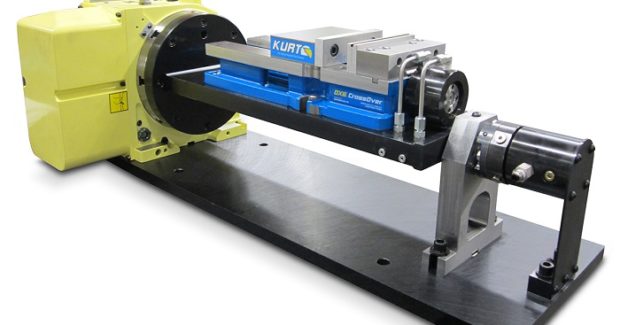

Rotary Table Workholding With Automated Hydraulic Clamping

Ideal for three-axis vertical machining centers, the Rotary Table Workholding System from Kurt uses a DX6 CrossOver Hydraulic vise with a trunnion mounted onto a 4-axis rotary table to provide three-side access to the part to be machined.

Big Bore Rotary Tables for Large Part Machining

For machining large diameter parts used mainly oil/energy applications, the Tsudakoma RCB Series extra-large center bore, dual disc hydraulic clamping rotary table from KOMA Precision uses a proprietary dual-lead worm gear system with ultra-precision cross roller bearings to deliver optimum balance between power, durability and smooth cutting performance.

Collet Rotary Table is Affordable Alternative to Chucks

Instead of using 3-jaw or 4-jaw chucks, the TJR AR-5C Pneumatic Collet Rotary Table from CNC Indexing & Feeding Technologies provides a highly rigid, accurate way to grip and index products suited for 5C collets.

Small, Powerful Plug-and-Play Rotary Tables

Compact, rigidly built rotary tables from KME CNC provide tremendous torque capacity and easily integrate with vertical machining centers to expand three-axis capabilities into four-axis, or four-axis capabilities into five-axis by simply mounting the rotary table right on any pallet.

Heavy Duty Tables Add Four-Axis Capabilities

Rugged HRT Series of T-slotted rotary tables from Haas can be mounted vertically or horizontally for added versatility in machining medium to large parts or fixtures.