Metal Stamping Press Automation Controller

To improve press room stamping operations, the SmartPAC PRO controller from Wintriss Controls enables networked users to share and view the entire contents of each programmed setup on a single screen in an Industry 4.0 environment.

Posted: June 5, 2019

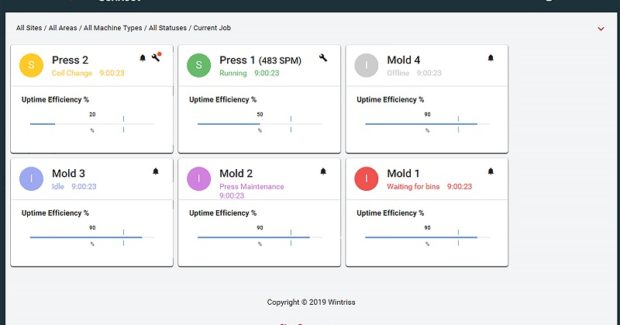

To substantially improve metal stamping operations, the SmartPAC PRO press automation controller from Wintriss Controls Group, LLC (Acton, MA) features a large, easy-to-use vivid touch screen interface, dual-core processors, user-configurable dashboards, virtually unlimited tool setup storage, the ability to share setups among networked SmartPAC PRO units and more. Its new tool summary screen enables users to view the entire contents of each programmed setup on a single screen, providing them with the ability to place notes for the job, and all content can be exported to a USB disk as comma-separated values. They can also create custom home screen dashboards to display the information they use most often. These dashboards can be named and saved in the favorites menu, and quickly recalled at any time. The system’s architecture supports advanced connectivity features, such as remote access from PCs and mobile devices, email messaging, and compatibility with IIoT production tracking OEE ShopFloorConnect™ software, which gathers production data from every machine in the factory, displays the Key Performance Indicators (KPIs) in real-time and produces detailed analytics, including comprehensive OEE reports in a variety of formats.

A Wonderware® hosting option enables the SmartPAC PRO to run independently-created third-party HMIs for associated automation, reducing the number of screens required on the press. System compatibility is maintained with previous legacy SmartPAC 1 and 2 modules, including the DiProPAC die protection system, ProCamPAC programmable limit switch, WaveFormPAC tonnage signature monitor, WPC 2000 Clutch/Brake control, and others. The SmartPAC PRO enclosure is also available with an optional Industrial Pendant Arm for mounting on presses.

ShopFloorConnect software can significantly increase manufacturing capacity and profitability by identifying and quantifying excessive production losses and bottlenecks. “Automatically collecting important efficiency and downtime machine data results in on-time, accurate reporting while removing subjectivity,” said Keith Magnant, the ShopFloorConnect sales manager. “This software provides an extremely easy-to-use, efficient data collection system that can reduce machine downtime by up to 70 percent.” This scalable and flexible production monitoring system is compatible with all ERP software, so it is well-suited for metal fabrication shops. It provides superior OEE calculations that accurately report overall equipment effectiveness for even the most complex manufacturing environments. The production tracking software provides machine downtime and manufacturing efficiency reports via a web browser and email, and integrates with existing systems.

Wintriss Controls Group LLC, 100 Discovery Way, Unit 110, Acton, MA 01720, 978-268-2700, Fax: 978-263-2048, www.wintriss.com.