Rotary Table Workholding With Automated Hydraulic Clamping

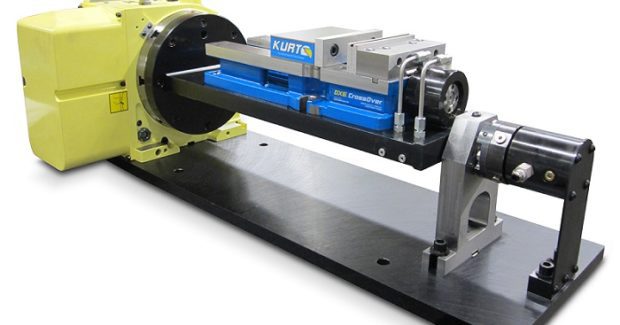

Ideal for three-axis vertical machining centers, the Rotary Table Workholding System from Kurt uses a DX6 CrossOver Hydraulic vise with a trunnion mounted onto a 4th-axis rotary table to provide three-side access to the part to be machined.

Posted: June 11, 2019

The Rotary Table Workholding System from Kurt Manufacturing Company (Minneapolis, MN) is designed with the DX6® CrossOver® Hydraulic vise with a trunnion mounted onto a 4th-axis rotary table. The system uses double-acting hydraulics that are desirable for automated part loading and unloading via a robotic system. It can also be used for manual part loading and unloading. The Rotary Table Workholding System is ideally suited for three-axis vertical machining centers and provides three-side access to the part to be machined. With the addition of this system, more complex machining and contouring work can be accomplished. Using the DX6 CrossOver Hydraulic vise, new levels in secure hydraulic gripping can be achieved. The vise is manufactured to the ideal flatness, parallelism and strength for critical high precision machining, with high clamping force to keep workpieces rigid as they are machined on each side. The vise features a ¼ in jaw stroke. The vise body also provides chip evacuation straight through the body at sides and end of vise to prevent chip build-up.

This system completely integrates the workholding, rotary table and mounting base. The DX6 CrossOver Hydraulic vise includes a GrooveLock® jaw plate and workstop for convenient part positioning. This vise has a larger and stronger bearing pack that increases durability and has longer life, and a new brush seal design for easier removal or replacement in the nut. An 80,000 psi ductile iron body, nut and movable jaw, a semi-hard steel screw and a hardened vise bed and jaw plates are also featured. These systems are produced by Kurt Custom Engineered Workholding and designed to exact specification and application requirements.

Kurt Manufacturing Company, Industrial Products Division, 9445 East River Road NW, Minneapolis, Minnesota 55433, 877-226-7823, Fax: 877-226-7828, workholding@kurt.com, www.kurtworkholding.com.