Smart Software Reduces Production Steps

Using a systematic approach to controlled tube manufacturing, t project software from transfluid connects CAD, BDE, ERP and shop intranet systems with tube bending machines and bending robots to make complex tube fabrication simple and safer and production less expensive.

Posted: June 3, 2019

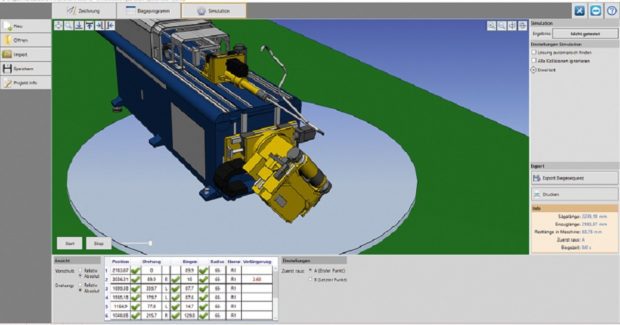

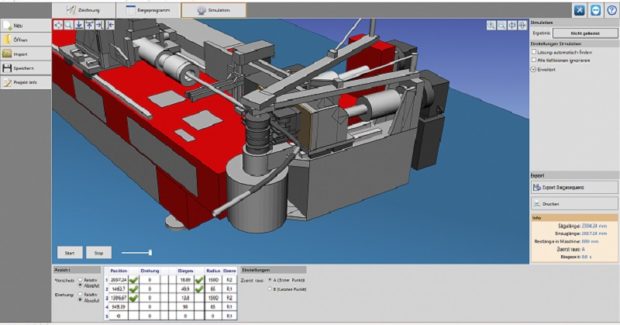

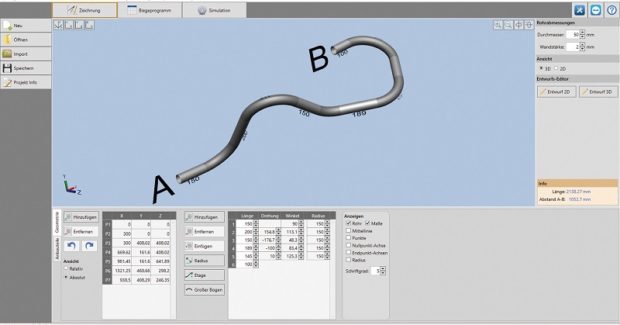

T project software from transfluid® Maschinenbau GmbH (Schmallenberg, Germany) reduces the number of steps necessary to manufacture a finished component, making production less expensive. An effective system for bending machines that can be used with any typical CAD system, it eliminates any possible collisions with the equipment, the tools or the environment before the actual bending process starts by testing the feasibility of the tube geometry and using necessary tool and machine parameters that are delivered online through the CAD system. If a robot is used for bending, T project processes the data without costly reprogramming of the robot by loading the data in the same format as a standard bending machine. It calculates all of the necessary robot movements, automatically adjusting bending speeds for product-specific processing of long tube, safely and without oscillations. It economically cuts tubes by optimizing the cutting pattern, calculating precision cut lengths that use fewer raw materials and are particularly effective for orbital chipless cutting.

The cutting sequence is prepared at the same time as the manufacturing process. Cutting is automatically improved and the semi-finished tubes can be used with as little waste as possible. The software connects directly to a shop intranet for higher data security. Individual part marking links to data connections or bending sequences that track the component through each stage of the manufacturing process and transfer data via common interfaces with CAD, ERP, tube bending machines, bending robots and other programs. Processes are visualized and validated by this Windows-based software, which intuitively accounts for the specific data of the material being processed to provide safe, accurate bending results. Additional modules contain entire process sequence details for better process control and management of the data used in the forming techniques.

Two new versions of t project software are available as isolated or networked options and play a key role in different areas of tube processing and custom solutions to make tube manufacturing safer. The first option, t project Basic, offers an almost complete digital basic package that can transform isometries into bending data directly and calculate correction and over-bending values automatically. By entering diagonal data for the space, the operator can control the bent component in an easy and manual manner. If the tubes have not been designed in the CAD system, it is also possible to enter the geometry manually. The second option, t project Professional, uses the same functions and more. Any necessary extensions are calculated automatically and additional production safety comes from the collision tests. If a potential collision is found, the software automatically finds an alternative. The Import module has 30 interfaces for IGES, STEP, JT, PCF and almost all of the most common programs to connect them to CAD, measuring equipment and Office programs. The system also has ten export interfaces to export data, such as IGES files.

The option to run tube simulations is helpful for practical applications such as flanges or forming. To calculate a whole package of tube geometries and test to confirm there are no collisions, the software uses a Multitest function to test all of the geometries by running calculations in the background, filtering out the process sequences that are not possible, and adjusting geometry as necessary.

For more information, look at other advances in tube and pipe fabrication and also subscribe to F&M.

transfluid Maschinenbau GmbH, Hünegräben 20-22, 57392 Schmallenberg, Germany, +49 2972 97150, www.transfluid.de.