3D Printing at a High Price/Performance Ratio

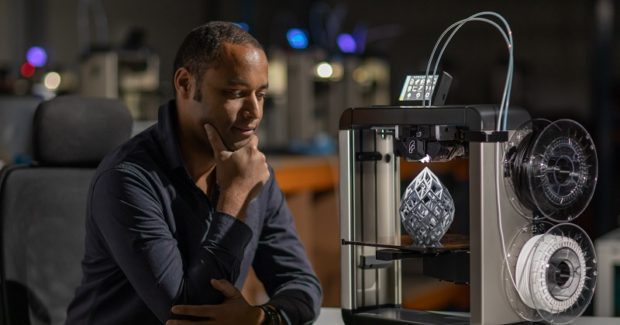

The economical Pro 3 additive platform from FELIXPrinters provides dual extrusion functionality, the ability to switch to a stainless steel nozzle for carbon reinforced printing, a larger build plate size and extreme layer resolution with low failure rates.

Posted: July 8, 2019

Recair B.V. (Waalwijk, The Netherlands) produces air-to-air heat exchangers from thin thermoformed sheets that are used in residential ventilation units to provide heat recovery of up to 90 percent. The success of their performance lies in design optimization through the adaptation of the thermoformed shape. Recair uses 3D printing for rapid prototyping, with some of their developments (such as measurement setups) being subject to incremental upgrades during product design. 3D printing gives them visibility of a prototype quickly and inexpensively, and allows the correction of design issues before costly tooling and manufacturing processes are initiated. Initially, the company outsourced all of their 3D printing requirements to subcontract agencies. They considered purchasing an industrial printer for in-house use, but postponed this decision due to the significant capital investment required to meet their quality needs. At that time, the volume of parts did not justify the expenditure.

However, as demand for higher volumes of 3D printed parts increased and the company required multiple prints, in-house ownership of a 3D printer became economically favorable. At this point, they approached FELIXPrinters (IJsselstein, The Netherlands) which builds highly accurate, reliable, easy-to-use and price-sensitive industrial AM machines. “There are a number of alternative additive options available to manufacturers, but not all machines are the same,” commented Stein Hendriks, a research and development engineer at Recair. “Supplier selection is a key to success, because the AM platform you choose must perform to the levels required for your specific applications. We ultimately chose their Pro 3 industrial 3D printing platform, which we use to fully optimize our designs without having to expend significant time and money. With a large amount of designs in development, the cost of prototyping with milling, injection molding or thermoforming is extremely costly and time consuming.”

One of the highest price/performance ratios in its class, the Pro 3 costs $2,912 and uses fused filament fabrication (FFF) technology to produce layer resolutions ranging from a low of 250 microns, normal of 200 microns, high of 100 microns, and extreme of 50 microns with a standard 0.35 mm nozzle diameter (optional 0.5 mm and 0.7 mm) and 1.75 mm filament diameter at build speeds up to 18 cu mm/sec (ABS @ 250 deg C). It can print PLA, PETG, ABS-X and PVA materials, as well as any filament that melts under 275 deg C for special applications. It has a build volume of 237 mm x 244 mm x 235 mm and is constructed from custom-designed anodized aluminum that is also used in aerospace and military designs. The build plate is a quick-swap magnetic flex-plate up to 105 deg C with fully automatic motorized leveling. The machine frame is made from powder-coated steel parts for maximum rigidity. Its dual head printing system operates within an open system that enables more design freedom. Emitting 32 dB of noise, the system is supposedly one of most silent printers available.

“We like to be able to get our hands on numerous prototypes early in the design-to-manufacturing cycle because this gives us a much better idea of the optimal nature of a design for end-use applications,” continued Hendriks. “We pick up design errors and flaws in the prototype that can be overlooked in a 3D CAD render – which are extremely expensive to correct once tooling has been cut and manufacturing initiated. We chose the Pro 3 for a number or reasons, including the dual extrusion functionality inherent in the platform and the ability to switch to a stainless steel nozzle for carbon reinforced printing. The larger size of the build plate and layer resolution was also a key factor in choosing this 3D printing system, as was its ease-of-use and low failure rates.”

FELIXPrinters, Zeemanlaan 15, Ijsselstein, 3401 NL, The Netherlands, +31 30 303 1387, www.felixprinters.com.