3D Printing Improves Aircraft Component Design

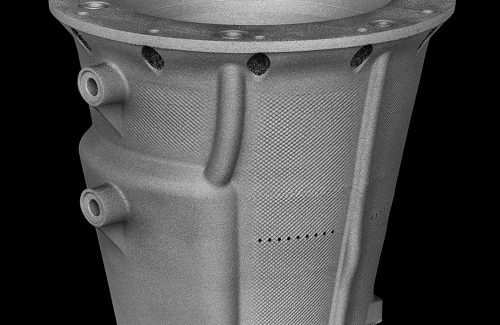

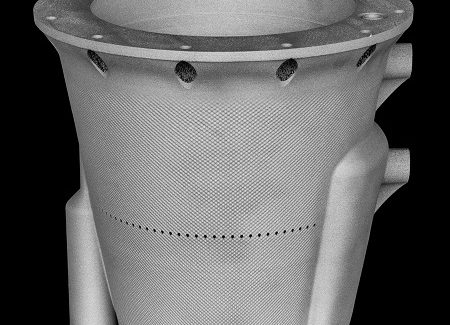

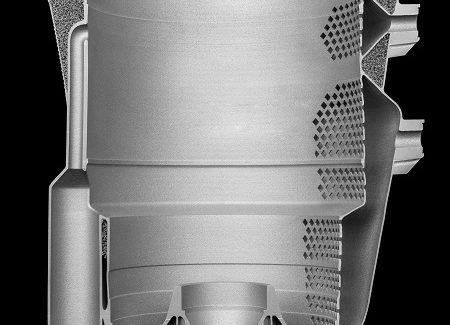

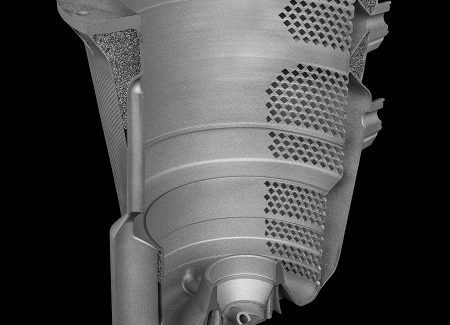

Betatype pushed laser powder bed fusion beyond its standard processes to create a more complex, higher density electrical generator housing for Safran Electrical & Power that performs better and has fewer parts, shorter delivery times and lower operating costs.

Posted: July 1, 2019

Safran Electrical & Power UK (Pitstone, England) designs and produces electrical systems for commercial and military aircraft for both fixed and rotary wing aircraft. With a desire to improve design knowledge – coupled with an increasing number of customers requesting parts to be made by additive manufacturing – the company knew they needed to enlist an AM design specialist. “We came across Betatype Ltd. (London, UK) in a search for 3D printing specialists and it was clear after our initial discussions that they had the knowledge and skillset we were looking for to add value in our new part production program,” said Dr. Mark Craig, a materials, special processes and composites expert at Safran whose job is to coordinate AM within the Power Division, where the 3D printing team was looking for ways to improve the design of an electrical generator housing. By exploiting the technical advantages of 3D printing, Betatype was able to improve the design of the housing by focusing on a number of key areas: improved strength, increased stiffness and a reduction in overall weight.

Betatype developed a proof of concept using an ultra-high density lattice as part of a sandwich structure with over ten million elements. “Creating a more complex, higher density lattice structure was the key to achieving what they were looking for in the part,” explained Sarat Babu, the chief executive officer of the Betatype. “Applying our technology and multi-scale approach, we were able to control the scan path and exposure settings down to each element of the sandwich structure’s design. By pushing the AM process of laser powder bed fusion well beyond its standard processes, we created the ultra-high density lattice structure required.” The proof of concept was a success, optimizing Safran generator housing designs for AM and unifying the design from several complex machined components into one part. This dramatically reduced overall part count and manufacturing times – adding value and saving costs.

Betatype Ltd., Unit 4 Bow Enterprise Park, 17 Fittleton Gardens, London, UK E3 3TZ, 44-20-7517-6985, www.betaty.pe.