Accurate Brazing Expands AM Capabilities

Their new Hot Isostatic Press from Quintus will be used for aircraft and ground turbine work.

Posted: July 23, 2019

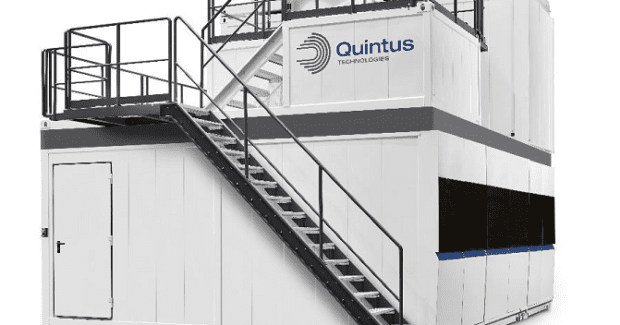

Accurate Brazing Corporation (Greenville, SC) is adding hot isostatic pressing to their thermal processing capabilities with the installation of a Hot Isostatic Press (HIP) from Quintus® Technologies (Västerås, Sweden). This QIH 122 M URC® press is equipped with proprietary uniform rapid cooling (URC) that improves material properties of parts designed for mission-critical applications, increasingly produced in the vibrant additive manufacturing (AM) environment. “We chose this equipment because of the advanced technology and the versatility of the design,” commented Steven Francis, the president of Accurate Brazing, a subsidiary of Netherlands-based Aalberts N.V., a major player in the global heat and surface treatment business, with more than 150 locations in 50 countries.

URC combines HIP and heat treatment in a single process, and High Pressure Heat Treatment (HPHT) streamlines the steps involved in material densification and heat treatment. This innovative approach enables all processed components to cool uniformly, resulting in minimal thermal distortion and non-uniform grain growth for improved parts performance. The HIP’s rapid cooling capability, at rates up to 390 deg F per minute, enhances efficiency and dramatically reduces processing cost per unit. “In today’s manufacturing environment, service businesses like ours need to constantly improve our capabilities, especially when it comes to meeting the tight timelines of the aircraft and ground turbine industries. And this new press will allow us to expand our product offering and compress overall lead times for our customers,” Francis noted.

Configured as a Quintus Modularized Solution, the space-saving and energy-saving profile of the press reduces infrastructure investment. The HIP will offer a work zone of 26.0 in (660 mm) diameter, 68.9 in (1,750 mm) height, and will operate at a maximum temperature of 2,552 def F and maximum pressure of 30,000 psi (2,070 bar). It will join the state-of-the-art equipment already operating in Accurate Brazing’s newest facility in Greenville, SC. Their AS9100 quality management system and Nadcap accreditation attest to their ability to meet the stringent needs of the aerospace and power generation industries. In addition to contracting with Quintus for full installation and commissioning, Accurate Brazing enrolled in the Quintus Care program for safe, trouble-free press operation and optimized functionality at a fixed annual cost. This program also provides access to in-depth technical expertise to support successful customer applications.