Added Value: The Importance of Aftermarket Care

You’ve covered every detail in upfront costs and factory floorspace, but what about technical support and service after production starts? Whether buying one robot or hundreds, having access to diverse support services to ensure peak robot performance is vital to maximizing your return on investment. Here’s why.

Posted: July 29, 2019

The use of advanced technologies and industrial robots for the purpose of welding continues to gain popularity, helping manufacturers deal with the lack of qualified welders, providing greater worker safety and optimizing product throughput and quality.1 And, with over 50 percent of manufacturers admitting they have an overall strategy to rely more heavily on automation over the next two years, the sale of robots should continue to be strong.2 From having a realistic automation strategy to robot design considerations, there is a lot that plays into purchasing a robot. While other aspects like upfront costs and factory floorspace are other valid concepts to consider, one key factor that is often overlooked is the value of aftermarket care. Whether a manufacturer is looking to purchase one robot or hundreds, having access to diverse support services to ensure peak robot performance while maximizing return on investment (ROI) is vital and should include:

TECHNICAL SUPPORT

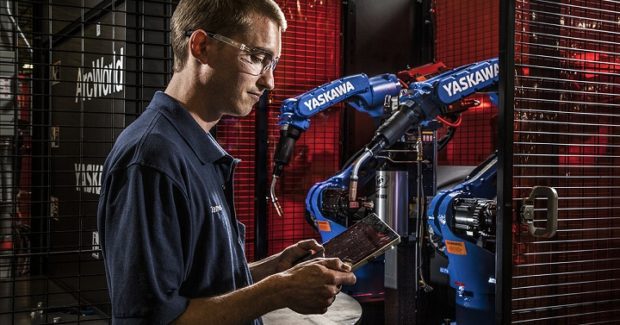

While extremely reliable, robots will require service at some point. Because robots are often crucial to meeting production demands, it is important to have 24/7 expert coverage that can help diagnose problems remotely. Whether it means accessing detailed how-to videos online or contacting technicians via a hotline, the robotic automation partner you choose should be committed to your company’s success, providing easy access to comprehensive technical support.

FIELD SERVICE

The key to minimizing downtime is receiving excellent field service support. In a customer-driven market that is becoming more demanding, a robot vendor that offers 24/7 dispatch by factory-trained field service technicians is ideal. These techs should be regionally located so that they are available in a timely manner, providing rapid on-site support for programming, maintenance, repairs and system audits. Those familiar with robot maintenance understand the importance of monitoring robot axes and keeping them well-lubricated to help control friction, vibration and heat. A reputable robot vendor should offer a routine grease analysis to maintain proper iron levels in the grease, avoiding costly repairs. More importantly, perhaps, is the ability for support personnel to fix an issue on the very first try. For this reason, buying a robot from a robot manufacturer or integrator that has a “first time fix rate” near 100 percent is very important.

PARTS

When it comes to maintaining operational success, having a vendor that has the right part, in stock, on time, every time is imperative. Robot manufacturers or integrators that provide 24/7 emergency parts availability with a high “first pass fill rate” are the best, mitigating downtime through dedicated spare parts support. Other key benefits to look for are a 12-month warranty on all parts, as well as spare parts packages and volume support packages based on your organizational needs and budget, ensuring that the necessary parts are available when robot mechanical system repair is needed.

TRAINING

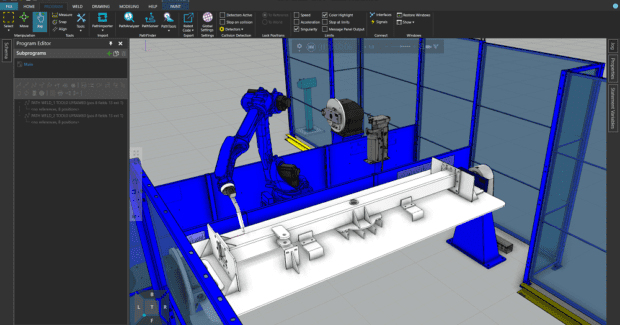

Because insufficient robot training can paralyze operations, it is essential to empower employees with the knowledge they need. Robot manufacturers that offer IACET accreditation courses at hands-on training facilities are highly recommended. World-class training locations (like our Yaskawa Academy) offer a 2:1 student-per-robot ratio and provide a comprehensive training curriculum utilizing application-specific classrooms and well-equipped welding labs. On the contrary, it is not always ideal for some manufacturers to send workers away to training. For this reason, some robot vendors offer remote and on-site training courses. Either way, robot manufacturers and integrators that have 95-100 percent customer satisfaction when it comes to training are a good option for company leaders looking for worker training that will provide the peace of mind necessary to run a top-notch operation. For manufacturers that cannot afford to interrupt production with training courses, comprehensive offline programming software (such as MotoSim® or OCTOPUZ®) enables individual operator training, as well as robot programming and optimization from the convenience of a desktop computer.

REPAIR AND RETROFIT

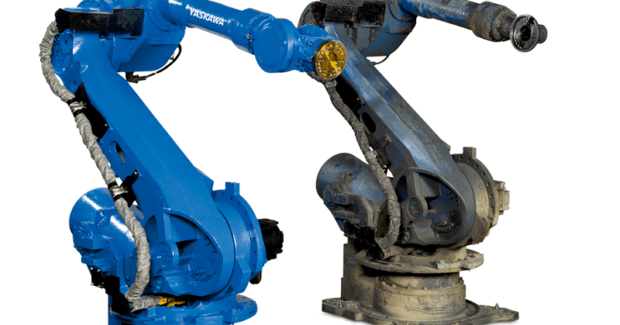

One way to dramatically increase productivity and profitability is by bringing aging robots and technology up to current standards through rebuilds, upgrades and retrofits. Ideal for extending the life of your existing robot(s), a robotic automation partner should be able to offer a range of modernization options:

- Small System Upgrades and Retrofits – often an add-on or change to existing peripheral equipment, small system modernization options are a good fit for meeting new program requirements or complying with new safety standards.

- Robot Rebuilds – from replacing the wire harness to changing-out the bearings, a thorough robot rebuild requires the ability to completely disassemble, clean and inspect a robot. Robot vendors should be savvy enough to complete robot rebuilds, as well as fully test them to meet/exceed original equipment specifications. Ideally, a service like this should come with a one-year warranty (or greater) on the total system.

- Repairs – because it is critical to keep automation running, various vendors offer extensive line of support agreements, depending on a company’s needs and budget. With detailed service plans and more, there are unique arrangements you can make to manage the life cycle of your robot. Approximately half of all industrial downtime is attributed to troubleshooting. For companies looking to diagnose mechanical issues in-house, some robot OEMs offer web-based maintenance systems (like RobotPro®) that provide step-by-step instructions for servicing a robot, saving time and money.

- Retrofits – while robots are built to last, there comes a time when the parts on your automation system become obsolete and require attention, or process needs change. One of the best ways to effectively manage the life cycle of a robot is through retrofitting, where an existing configuration is changed or upgraded on original equipment. While the thought of retrofitting may bring uncertainty and require budgeting, working with a knowledgeable robot vendor can walk you through the process. Regardless of the reasons, retrofitting keeps up with the latest technology, reducing energy consumption and maintaining competitive advantage.

- Core Exchange Program – when faced with the dilemma of buying a new robot, it is helpful when robotic automation partners offer unique, more affordable options for robot replacement. Some robot vendors offer programs where popular robot models are rebuilt and exchanged for “aged” robots. This is also advantageous because the exchange is often quick, decreasing potential production downtime.

- Certified Pre-Owned Robots – for manufacturers just starting out or job shops on a tight budget, buying a certified pre-owned robot from a reputable vendor is often the best first step to robot ownership. Buyers seeking pre-owned robots should be sure each robot has undergone rigorous 60+ point testing and a detailed inspection process. Most importantly, the robot should be calibrated to ensure accuracy.

LIFE CYCLE MANAGEMENT

The growing demand for mass product customization with more accurate supply chain synchronization and faster multichannel retail responsiveness is changing the fundamental model of manufacturing, putting greater value on maintaining peak robot performance.3 To better facilitate this, management should consider implementing robotic technologies managed by factory automation systems that can monitor, accumulate and visually deliver data in real-time for networked production environments. This allows for data-driven optimized planning for preventive and predictive maintenance, creating more productive factories. Robot vendors that offer heterogenous systems (like Yaskawa Cockpit™) are ahead of the curve.

MAXIMIZING PERFORMANCE

Doing your research when it comes to these areas can maximize equipment utilization and robot performance, optimizing ROI. In a demanding market that bombards manufacturers with unique product specifications, finding a committed robotic automation partner that can tailor support programs that help avoid unplanned downtime while extending the life of your robot is a smart choice for making the most of your welding robot purchase.

References

- Welding Trends 2019, Welding Value, 2019,

- 2018 Deloitte and The Manufacturing Institute Skills Gap and the Future of Work Study, 2018.

- AI and Robotics Automation in Consumer-Driven Supply Chains, The Consumer Goods Forum, 2018.