Build Preparation is No Longer an Afterthought

Flow software from Velo3D integrates print preparation, simulation and composing capabilities to predict and control the outcome of building any design and assure its accuracy and consistency.

Posted: July 9, 2019

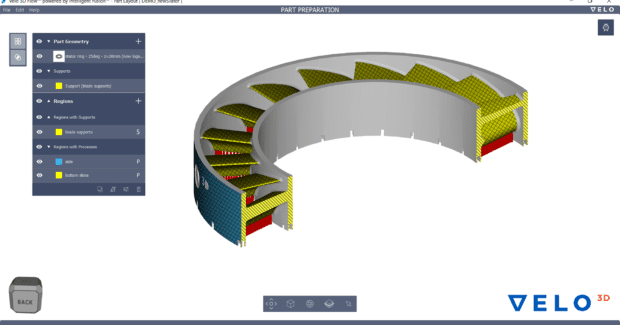

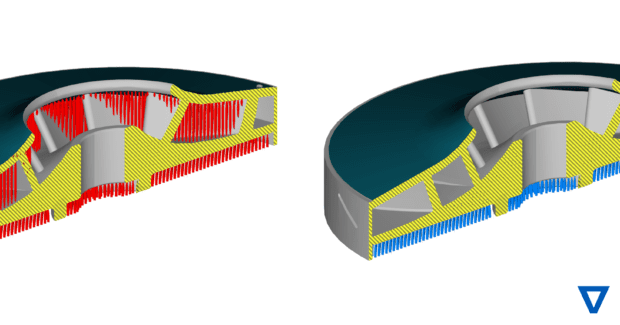

Flow™ print preparation software from Velo3D™ (Campbell, CA) is driven by a powerful integrated simulation engine that ensures predictable print outcomes, while its native CAD workflow controls performance consistent with the design intent and significantly reduces print preparation time. Specifically designed to work with the Sapphire™ laser fusion metal additive manufacturing system, Flow enables next generation SupportFree™ additive manufacturing for parts previously not possible. It includes tools that help with part orientation, support generation, simulated print predictions, per-surface process application, slice composer and process review. This means shops can now print complex part geometries SupportFree, enabling volume manufacturing of parts that are otherwise impossible or uneconomical to print due to hard-to-remove support structures.

The ability to print low angles and overhangs below five degrees, as well as large inner diameters and tubes up to 40 mm without the need for supports, eliminates the need for difficult and laborious post-processing cleanup. This capability breaks the limiting boundary of other systems that require supports for most angles below 45 deg, constraining design freedom and limiting the number of designs that can be produced with additive technology. Key features of this system include:

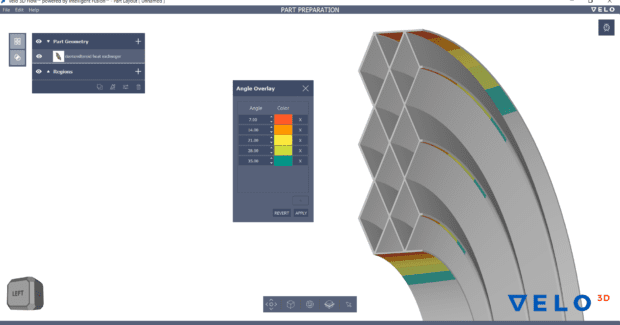

- A new physics-driven simulation engine has been built from the ground up, optimized for Velo3D process capabilities and the Sapphire system. It contributes to achieving a first-print success rate of up to 90 percent, preventing many failed iterations.

- The powerful simulation utility predicts the print outcome, applying print deformation correction and validating the execution feasibility of the print prior to starting the build process. It ensures that the print outcome results in dimensionally-accurate design intent.

- A sophisticated composer detects geometric features and applies the optimized, proven print process to specific features, delivering predictable print outcomes.

The integration of print preparation, simulation and composing capabilities into a single software eliminates historic incompatibilities, significantly simplifying the workflow. Native CAD workflow enables new user experience with smart selection, refinement, and filtering of part features and reduces hundreds of manual steps to a few clicks so that users can focus their efforts on solving problems on the application level, instead of troubleshooting machine level parameters. This is the first and only print preparation software that manages print outcome based on the design intent. With the native CAD import, the design intent is preserved and users can optimize for target cost and quality parameters by surface. It enables selection of areas to optimize the surface finish, and others for throughput. Flow allows the user to optimize a print within the design requirements by delivering the highest possible quality for critical surfaces, while non-critical surfaces can be optimized for throughput.

“Build preparation software has always been an afterthought,” said Benny Buller, the chief executive officer of Velo3D. “This system is process driven, where the software manages the hardware and can predict and control the outcome – the only way to manufacture any design, assure accuracy and consistency, and take additive manufacturing mainstream.”

Velo3D, 511 Division Street, Campbell, CA 95008, 408-610-3915, info@velo3d.com, www.velo3d.com.