Fume Extraction Enters the Digital Age

Highly efficient WeldFil central extraction and filtration systems from Kemper use sensor technology and cloud-based data communications to make predictive maintenance a reality.

Posted: July 15, 2019

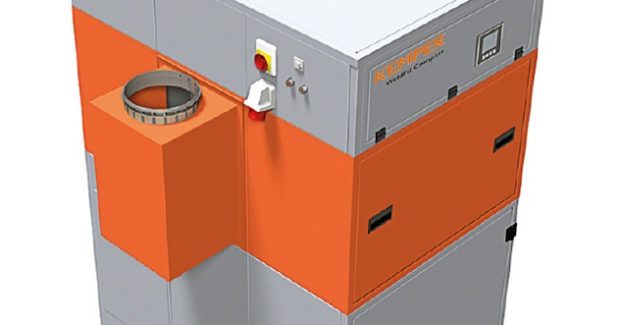

With their WeldFil series, Kemper GmbH (Vreden, Germany) takes central extraction and filtration systems into the digital age with systems that are not only internet-compatible, but also comprehensively optimized in expenditure of energy, maintenance needs and design. WeldFil replaces earlier central 8000 and 9000 extraction systems and can be divided into the smaller plug-and-play WeldFil Compact and the WeldFil for larger installations. A new construction enables simple access to important components – such as the fan, filter cartridges or the compressed-air maintenance unit – that reduces maintenance costs for the system operator. The combination of motor and fan is optimized with new and more efficient interaction that allows the system constructor to reduce the motor power in some cases up to 40 percent, from 37 kW down to only 22 kW, making these new systems particularly energy efficient.

WeldFil meets all requirements regarding volume flow and filter area. With low noise emission of a maximum 65 dB(A), Weldfil installations are some of the quietest on the market. This system makes the leap into Industry 4.0 with new sensor technology and a cloud-based internet-compatible control module. Important information, such as differential pressure, temperature or residual dust monitoring are easily retrievable online. “This makes automated, rule-based processes possible for central extraction systems,” explained Björn Kemper, the managing director of the company. “Predictive maintenance becomes reality for extraction technology.” A generation change in central extraction and filtration systems is introduced with a modern design that makes maintenance of installations easier. A new base frame offers better corrosion protection, particularly when installed outside.

Kemper America Inc., 1110 Ridgeland Parkway, Suite 110, Alpharetta, GA 30004, 770-416-7070, Fax: 770-828-0643, kemperamerica.com.