Next Generation Controlled Atmosphere DED Systems

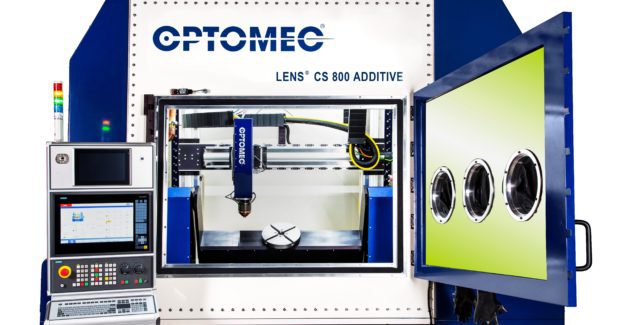

LENS CS 600 and CS 800 Controlled Atmosphere (CA) DED systems from Optomec provide high cost-to-performance ratios on demanding jobs ranging from precision deposition to cladding applications.

Posted: July 9, 2019

The LENS CS 600 and CS 800 Controlled Atmosphere (CA) DED systems from Optomec Inc. (Albuquerque, NM) are configurable and maximize the process build envelope with a minimal system footprint. “These Laser Engineered Net Shaping (LENS) systems come packed with next-generation directed energy deposition (DED) components all born from our signature know-how and built to provide affordable, high-quality metal additive manufacturing capabilities for the most demanding requirements,” said Tom Cobbs, the Optomec LENS product manager. “These two systems represent the latest in DED processing, from precision deposition to cladding applications.” Both machines come standard with controlled atmosphere chambers for processing of both non-reactive and reactive metals in an atmosphere that keeps moisture and oxygen levels at less than 10 ppm. Also standard is a powerful Siemens 840D controller that allows for smooth and sophisticated 3D printing, from three-axis up to simultaneous five-axis motion.

These two systems are also compatible with the latest generation LENS deposition head that provides higher power laser processing (up to 3 kW), interchangeable print nozzles, and variable spot sizes. LENS systems use DED technology, where high-powered lasers build structures layer-by-layer directly from powdered metals, alloys, ceramics, or composites to produce fully-dense parts with excellent mechanical and fatigue properties. The LENS CS 600 and CS 800 systems are designed to maximize the LENS process build envelope while minimizing chamber volume and system footprint. The base LENS machines are equipped with a linear three-axis motion system, but optionally can be delivered with a user interchangeable rotary table and/or tilt-rotate trunnion for four-axis and five-axis operations. The Siemens motion controller provides an easy-to-use push button HMI and utilizes industry standard G&M codes to drive the system. Optional material starter recipes, closed loop process controls, thermal imaging, five-axis tool path generation software, and unparalleled customer service round out these two systems.

These machines incorporate LENS 3D metal printing technology for higher power and faster additive manufacturing. One unique advantage of LENS is that it is able to add metal to existing parts for repair and coating applications that extend the useful life of components without the need to re-fixture or align the component on a second machine. These two machines have a high cost-to-performance ratio.

Optomec Inc., 3911 Singer NE, Albuquerque, NM 87109, 505-761-8250, Fax: 505-761-6638, www.optomec.com.