Robot Transports Heavy Loads Using AI-Based Navigation

With the ability to distinguish between humans, forklifts and other obstacles and react for greater efficiency, the large MiR1000 autonomous mobile robot from MiR can safely lift and efficiently transport a 2,200 lb payload.

Posted: July 16, 2019

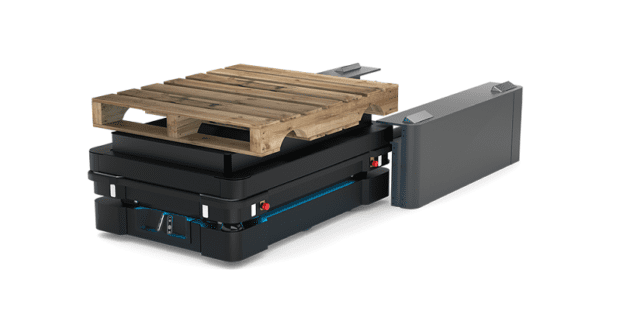

The large MiR1000 autonomous mobile robot (AMR) from Mobile Industrial Robots Inc. (MiR; Holbrook, NY) can automatically pick up, transport and deliver pallets and other heavy loads up to 1000 kg (2,200 lbs.) through dynamic environments using artificial intelligence (AI) capabilities for improved navigation. This is a collaborative, safe and flexible alternative to potentially dangerous and expensive forklifts used on the factory floor.

The MiR1000 has been developed in response to strong demand from users of smaller robots who also want to transport very large, heavy materials – such as those in the aerospace and automotive industries – without reconfiguring their infrastructure.

“Manufacturers today must deal with ever-changing customer demands, which means they need flexible and easily adaptable production facilities,” said Thomas Visti, chief executive officer of MiR. “Conventional logistics systems, such as forklifts and conveyor belts and even traditional automated guided vehicles, haven’t been able to support this type of production. But the MIR1000 requires no rebuilding of infrastructure or extensive programming capabilities. It is especially easy to optimize the transportation of all types of materials and much heavier loads.”

With AI capabilities incorporated into the software and strategically placed cameras that function as an extended set of robot sensors, this robot is optimized for route-planning and driving behavior.

The cameras, called AI Camera, enable the robot to detect and recognize different moving obstacles and react accordingly. For example, the robot will continue driving as usual if it detects a person, but will park if it detects an AGV so that the AGV can drive by.

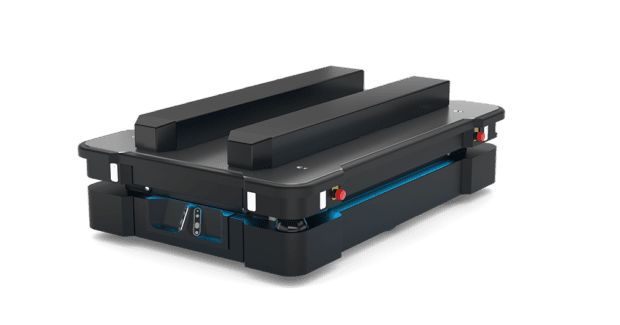

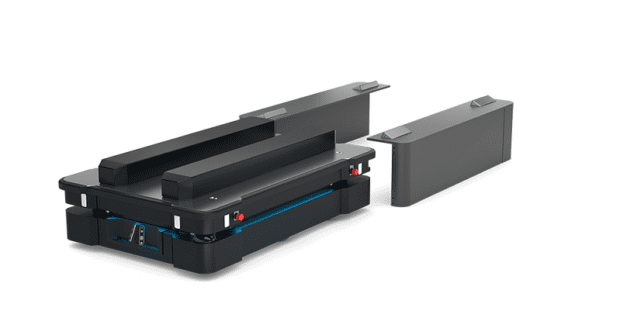

The robot can also predict blocked areas or highly trafficked areas in advance and reroute instead of entering the blocked area and then re-routing. The MiR1000 has two flexible pallet lifts for the two most commonly used types of pallets: the EU pallet and the 40 in x 48 in pallet. It can be programmed via the intuitive user interface or through the MiRFleet robot fleet management system, which makes it simple to automate new tasks for a shop’s entire fleet of robots. The AMR can also easily integrate different top modules to support a wide range of applications, such as pallet lifts, conveyors, a robot arm or other options.

www.mobile-industrial-robots.com