Shaping the Future of Manufacturing

3D printing capabilities in various additive systems from Cincinnati Incorporated range from quickly creating prototypes to unattended production of complex parts, with part simulation in all stages of fabrication that dramatically reduces waste in part design and accelerates advancement to production.

Posted: July 1, 2019

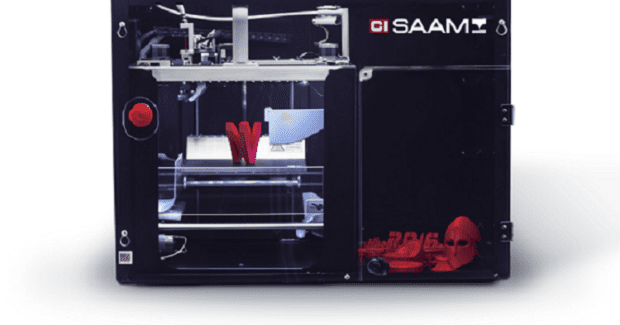

Originally designed to complement their BAAM (Big Area Additive Manufacturing) and MAAM (Medium Area Additive Manufacturing) machines, Small Area Additive Manufacturing (SAAM) machines from Cincinnati Incorporated (CI; Harrison, OH) provide an array of 3D printing capabilities: SAAM and SAAM-HT 3D printers allow for prototypes to be created before entering full-scale production on those larger additive machines, and are ideal for creating functional parts as well. These machines use fused filament fabrication (FFF) technology to 3D print composite or plastic parts directly from a CAD design. They can form any shape imaginable and are certified to print in carbon fiber nylon and PLA. The system allows designers to prove-out part designs while saving material and time. SAAM also simulates parts produced by non-additive machines. The same CAD file used for the prototype can be sent to a laser, a press brake, or a shear for metal fabrication to dramatically reduce waste in the design process and accelerate advancement to production phase.

These machines are small enough to fit on desktops and similar surfaces, making them the ideal system for using additive manufacturing capabilities to create functional parts in limited spaces. Both machines utilize the patented Automated Ejection System to provide the capability for continuous, unattended 3D printing. Optimized for carbon-fiber composite 3D printing, SAAM boasts a 6061 aluminum and steel frame and a heated-bed temperature of 90 deg C (194 deg F). The SAAM HT has the same ease and speed of the SAAM machine, but offers more power and a wider range of options. It features the ability to 3D print in ULTEMÔ 9085 PEI, PEEK, CarbonXÔ, carbon fiber-nylon, Makeshaper PLA Spool or any thermoplastic up to 500 deg C (260 deg F). All of these options make this machine one of the most affordable systems for 3D metal fabrication, whether a shop is looking to create prototypes or strong, functional parts.

CI offers a new carbon fiber resin material for their SAAM 3D printers that is impact resistant, lightweight and has a very high strength-to-weight ratio. Carbon fiber reinforcement makes the material stiff, durable and very low warping – and advanced inter-layer adhesion results in accurate, quality parts with good dimensions. This material’s superior surface finish makes it perfect for custom tooling applications, as well as assembly, CMM, welding and CNC fixtures. “This material advances additive applications on the shop floor, allowing on-the-spot production of custom tooling and fixturing that saves time and money,” said Chris Haid, the general manager of the NVBOTS business unit at CI. “Additive has opened a new world for parts designers and engineers, and now SAAM allows shops to fabricate custom tools and fixtures easily and quickly. This material is very durable and it has been tested, qualified and certified to be compatible with SAAM – another example of how additive is shaping the future of manufacturing.”

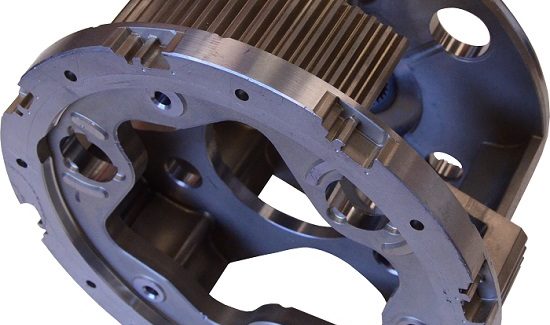

CI also provides a broad spectrum of additive manufacturing capabilities through Powder Metal Compacting Presses that are designed to deliver high production rates and accuracy. This family of machines includes a die-set press, a platen assembly press and a hybrid press. The Parts Maker, Fast Set-Up, and Rigid Reflex are all mechanical presses that offer multi-level part capability, a press control center and programmable feeder systems. The Rigid Reflex press uses rugged precision guiding for compacting complex parts with possible off-center loads. The hybrid press is the Power Die Change, which also offers multi-level part capability and a press control center. It features the speed and accuracy of a mechanical press while still allowing the user a level of control only found with a hydraulic press. Exclusive to this machine is the unique ability for tri-press stops that allow the machine to produce complex parts with excellent press stop positioning, ensuring the production of precise parts. The Rigid Restrike press is designed for sizing and coining operations. It uses a steel welded construction tie rod design to handle high impact loads.

Cincinnati Incorporated, 7420 Kilby Road, Harrison, OH 45030, 513-367-7100, info@e-ci.com, www.e-ci.com.