Software to Automate Build Preparation, Monitor the Build Process

Renishaw offers QuantAM Dental to cut build preparation time for hundreds of dental frameworks in a single operation, and InfiniAM Spectral to analyze process monitoring data in real-time.

Posted: July 9, 2019

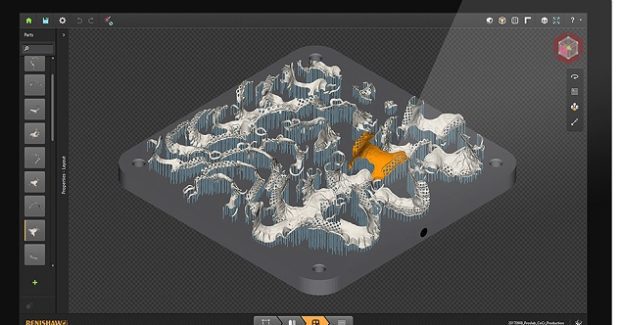

QuantAM Dental software from Renishaw Inc. (West Dundee, IL) automates additive manufacturing (AM) build preparation for hundreds of dental frameworks in a single operation. It can cut preparation time from two hours or more with existing build preparation software to around 30 minutes – a 75 percent reduction that allows dental production facilities to produce patient-specific frameworks with a reduced workload for staff that enables cost reductions. Dental production facilities typically receive hundreds of custom design files daily from multiple customers. Previously, the industry lacked a single suite of software that could handle all the operations required to prepare files for production. Instead, manufacturers were forced to use multiple software applications to prepare for a build. “This software consolidates the number of software packages required to produce batches of frameworks, helping to reduce licensing overheads, decrease training requirements and reduce build preparation times daily,” explained Ed Littlewood, the marketing manager of Renishaw’s Medical and Dental Products Division. “Being able to start builds later in the working day allows more time for designs to be received from customers, leading to a fuller build plate and better production efficiency, whilst still allowing the build to complete before the next working day.”

QuantAM Dental automatically imports hundreds of dental frameworks, repairs the stereolithography (.stl) files if necessary and automates the orientation so that framework cavities face upwards, avoiding supports on the fitting surfaces. It also automatically adds an identification tag to each framework to allow reconciliation to designs and finally, generates supports. The software then groups framework types according to manufacturing requirements. For example, frameworks that require heat treatment, such as bridges, are grouped separately from those that do not. Frameworks not requiring heat treatment can quickly and easily be identified before that step in the process is completed. Finally, it reviews the files and gives a list of potential errors for any sub-optimal frameworks. The systems operator can then slice the build files ready to transfer them to the AM system.

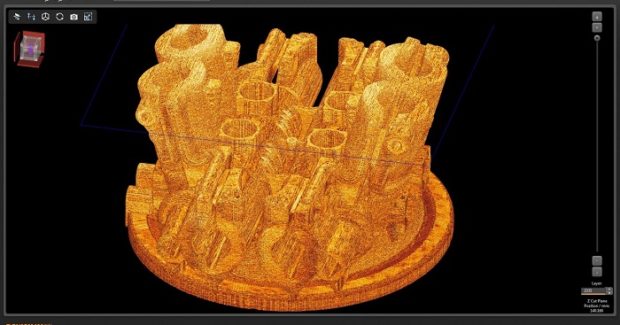

Renishaw also offers InfiniAM Spectral, an AM process monitoring software developed for use on Renishaw systems. It helps AM users gain a greater understanding of their processes and overcome the difficulties with AM in critical applications, process stability and part quality. This software is part of a developing family of products that help users capture, evaluate, present and store process data from laser powder-bed fusion (LPBF) technologies. It offers two measurement functions in the sensor modules: The first module, LaserVIEW, uses a photosensitive diode to measure the intensity of the laser energy. The second module, MeltVIEW, captures emissions from the melt pool in the near-infrared and infrared spectral ranges. MeltVIEW and LaserVIEW stream data across a conventional computer network on a layer-by-layer basis, so manufacturers can analyze process monitoring data in real-time. As the build progresses, the data is rendered live in 3D for viewing in InfiniAM Spectral. The engineer can compare the data from each sensor to identify any deviations, which may indicate the presence of anomalies that could lead to defects.

“The amount of process data generated during an AM build is immense, which means it can be difficult to make practical use of it without the correct interpretation tools,” explained Robin Weston, the marketing manager of Renishaw’s Additive Manufacturing Products Division. “This software is hugely beneficial to manufacturers because it allows them to easily translate the data, which leads to more consistent AM outcomes.”

Renishaw, Inc., 1001 Wesemann Drive, West Dundee, IL 60118, 847-286-9953, www.renishaw.com.