Spindle Diagnostics: Predictive Maintenance at Your Service

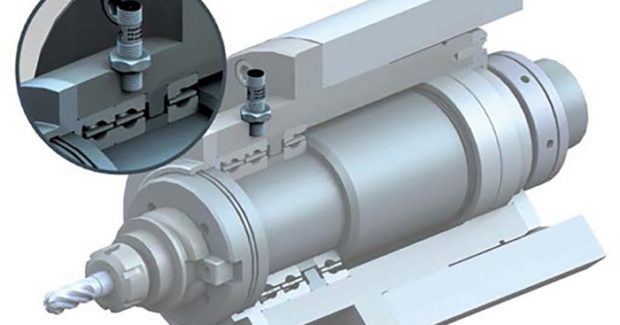

Installed directly into the spindle, the miniaturized B-Safe system from Diamond Industrial Tools uses vibration and temperature analysis for real-time monitoring of anomalies, predicting malfunctions and reducing machine downtime.

Posted: July 25, 2019

The miniaturized B-Safe system from Diamond Industrial Tools, Inc. (Lincolnwood, IL) is a new idea for spindles and machine tools diagnostics according to vibration and temperature analysis. This miniaturized system can be installed directly into the spindle, guaranteeing real-time monitoring about all anomalies, predicting malfunctions and reducing machine downtime. Its hybrid MEMS 3D and piezoelectric technology guarantees complete signals analysis on a wide band. The presence of a microprocessor with integrated memory allows local detection and memorization of collision phenomena, unbalances, overloads, anomalies of the working cycle, tools wear and bearings diagnostics. The B-Safe Spindle Check-Up function includes a series of algorithms to check the efficiency level of the productive process, with the aim of maximizing the productivity of machine tools and the quality of parts being produced. The statistical analysis provided by the system provides essential support for planning maintenance interventions according to actual use of the equipment.

B-Safe is an interconnected system that combines advanced technologies for analysis and supervision of machinery in the manufacturing plant, including:

- Collision protection function that triggers instant stoppage of the machine.

- Continuous monitoring function continues to record data even when the machine is off.

- Black box operations through an embedded data logger.

- Industry 4.0 upgrade of connectivity and information sharing.

Diamond Industrial Tools, Inc., 6712 North Crawford Avenue, Lincolnwood, IL 60712-3587, 800-227-5905, Fax: 800-441-7771, moreinfo@todit.com, www.todit.com.