The New Age of Mold Making

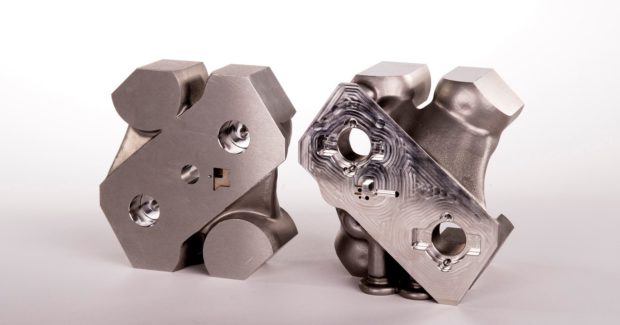

Used in making plastic components for optical applications, this 3D printed mold from toolcraft has optimized topology, is smaller and weighs less, is easier to manufacture and significantly improves the process of producing the plastic parts.

Posted: July 9, 2019

MBFZ toolcraft GmbH (Georgensgmünd, Germany) unites seven divisions under one roof. An in-house project conducted with their partner Siemens demonstrates how these lines of business work together in a mutually beneficial way. The starting point was a mold for manufacturing a plastic component for the optical industry. The opportunities created by 3D metal printing allow new avenues to be explored and molds to be completely reimagined. The result was a mold with an optimized topology that is not only easier to manufacture, but also significantly improves the process of producing the plastic component. The tool used-to-date comprises mold inserts, mold plates, mounting plates and standardized components. It measures around 125 mm x 125 mm x 130 mm and weighs approximately 60 kg. The objective of the project was to improve the injection molding process in terms of its cycle time to make the unit less complex and to simplify the development process.

The considerable flexibility offered by 3D metal printing meant the design engineer could completely reconfigure the insert and improve its topology in line with the specific loads and requirements, creating a brand new mold that is smaller and lighter, with integrated conformal cooling. “Certain surfaces had to be retained during the topology optimization process in order to preserve the functionality of the mold,” said Ralf Domider, the head of design and simulation metal laser melting at toolcraft. “Special requirements, such as the need for both parts to fit together precisely, the position of the ejector and the connectors for the machine’s peripherals, had to be taken into account when optimizing the topology.” Options for later clamping the mold for reworking in a CNC machining center also had to be considered during the design stage. In order to make full use of the technological advantages of additive manufacturing, functional surfaces, such as a conformal cooling channel with an optimized cross-sectional area, were integrated into the blank.

A further challenge was the warping of components during the 3D metal printing process. Arranging the components in the best way possible and creating the necessary supports require an in-depth understanding of the process, as well as experience in preparing data for additive manufacturing. This also has a strong influence on component warping. With the support of integrated process simulation, this warping can be calculated quickly and efficiently to avoid unwanted rejected components or disruptions in the construction process from the outset. The “first time right” principle is an important indicator for the technological maturity of additive manufacturing and is especially crucial for industrial applications. After redesigning the mold, the designer extracts functional surfaces, specifies the framework conditions, and selects the material. This is followed by the integration of conformal cooling, topology optimization and verification using FEM calculation and cooling simulation. The data is then prepared for printing.

The simulation of the printing process is followed by production and finishing, from heat treatment, removal of supporting structure, surface treatment to machining reworking as well as optical and tactile quality control. The new and improved 3D printed mold has much smaller dimensions. “The original unit that comprised several individual components has been reduced to a mold half,” noted Domider. “The optimized tool now weighs almost 50 percent less than its predecessor.” This low weight means that less mechanical power is required and makes the mold easier to assemble into the injection molding machine. At the same time, the tool is much higher performing despite the shorter development period. The lower mass and the conformal cooling reduces the cycle time by 30 percent, while ensuring that the component quality remains the same.

MBFZ toolcraft GmbH, Handelsstraße 1, Georgensgmünd, Germany 91166, +49 (0) 91 72/69 56-0, toolcraft@toolcraft.de, www.toolcraft.de.