Why the Cheapest Powder Doesn’t Produce the Cheapest Parts

Additive manufacturing may be at the cutting edge of production technology, but LPW Technology proves how the old rule still applies when it comes to the quality of material: buy cheap, buy twice.

Posted: July 8, 2019

For LPW Technology Ltd. (Widnes, UK), ‘quality’ material for additive manufacturing translates into consistency of supply, full traceability and reliable material performance. Consistency of supply and traceability are factors which are controlled by robust quality management systems, optimized manufacturing methods and trusted supply chains, but material performance is driven by the properties of the powder itself. One of the key benefits of AM over conventional manufacturing is the ability to reuse a batch of material that has been through the process. The business case for reusing powder is strong: the more times you can reuse a batch of powder, the lower the final cost per part is on the basis of less powder ‘wasted.’ The number of times a material can be reused is often determined by the user or a perceived industry standard, but either way material performance in delivering as-built parts is typically the key metric.

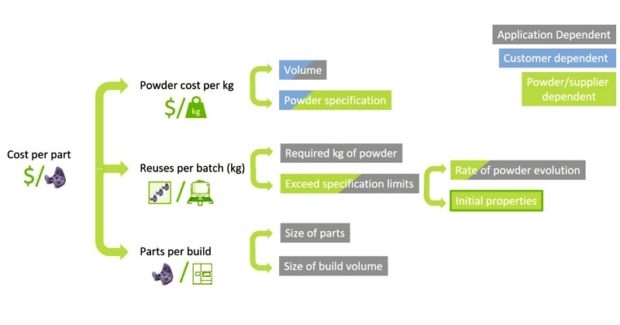

If we consider the final cost per part, there are actually a number of key factors that can influence this cost (see Figure 1). As with conventional manufacturing, material is generally seen as the highest cost factor in ongoing production, but powder reuse means that the final cost per part does not have to reflect the initial powder cost per kilo. Two other key factors are: how many viable builds can be completed from a single batch of powder and how many parts can be produced in each build. The number of parts produced in a single build is entirely application specific and depends on the size of the part and the size of the available build volume. The number of builds that can be completed for a single batch is dependent on how quickly the powder breaches the specification limits. At this point we must consider the influence of powder evolution, or how a material varies from initial specification.

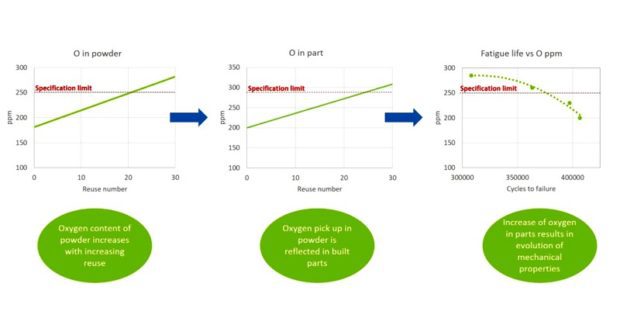

LPW has demonstrated how metal powder evolves with reuse (see Figure 2). Oxygen concentration in the powder has been shown to increase linearly with number of reuses and this increase is reflected in the parts. For Inconel 718, this has the potential to influence the dynamic mechanical performance of a component. LPW demonstrated that an increase of oxygen content of 50 ppm was sufficient to significantly reduce the fatigue life of the material at elevated temperatures. Where this linear relationship is demonstrated, it is logical that starting with a virgin powder with lower oxygen levels will allow more builds to be completed before the specification limit is reached. Oxygen levels in powder are primarily driven by oxygen levels in the feedstock material and the process parameters and gas purity used during atomization. For this reason, it is typically more costly to produce powders with low oxygen levels.

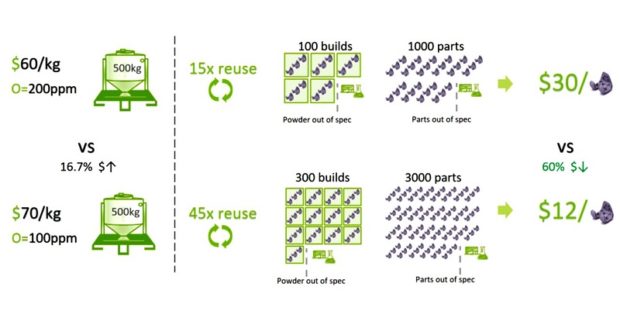

It may seem more cost effective to use powder with a higher oxygen content but at a lower cost, but this is only true if a user does not consider reusing the metal powder. Figure 3 compares the total cost of ownership of two batches of Inconel 718 powder. The first batch has an oxygen content of 200 ppm (0.02 weight percent), with a cost of $60 per kg. The second has an oxygen content of 100 ppm (0.01 weight percent) with a cost of $70 per kg – a 16.7 percent increase, which for large batch sizes represents a significant material cost. Although Batch 2 is more costly per kg, it is also 100 ppm lower in oxygen, so what is the impact of that 100 ppm reduction in oxygen content? If we take a material specification limit of 250 ppm and apply the modest oxygen evolution rate of 3.5 ppm per build, we find we can achieve triple the number of reuses with the lower oxygen powder. This means that despite a 16.7 percent increase in material cost, we actually see a 60 percent reduction in the final cost per part vs. the cheaper, higher oxygen content powder.

The confidence to reuse powder has changed the business case landscape for metal additive manufacturing. The use of high quality material is not only to achieve optimum results from a single use, but to extend the commercial and specification life of the powder. Additive manufacturing may be at the cutting edge of manufacturing technology, but in this case the old rule still applies: buy cheap, buy twice.

LPW Technology Ltd., Dennis Road, Widnes, Cheshire, UK WA8 0GU, +44 1928 240530, www.lpwtechnology.com.