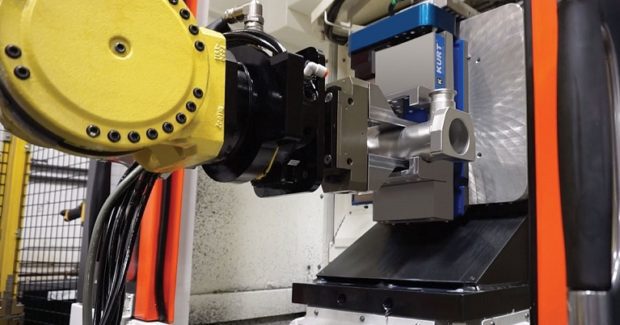

Air Powered Vise Handles Parts in Robotic Machining Cell

For part handling that requires consistent clamping not easily attained by manual operation, the motorized air vise from Kurt delivers robust clamping repeatability, consistent preset clamping force and programmability of the vise opening if desired.

Posted: August 8, 2019

When an equipment manufacturer wanted to automate part clamping for a high volume casting to be machined in a robot-attended machining cell, they turned to Kurt Workholding Company (Minneapolis, MN) for support. After reviewing the initial machining cell and part requirements, engineers drew upon past workholding experience and designs, along with some new developing ideas in air powering workholding systems. With shop air readily available in most manufacturing plants, they selected to work with the available air supply vs. deploying an additional costly hydraulic pump system. Drawing upon the 3600V vise design that provides robust clamping repeatability, the engineers integrated a newly developed air motor configuration along the outside of the vise base to actuate the moveable jaws. The new system included all air motor components, sensors for predetermined jaw stop, push-to-connect air fittings and sine keys for table mounting.

The motorized air vises provide consistent preset clamping force and programmability of the vise opening if desired. These air vises integrate with automation, robotized cells, and applications requiring consistent clamping not easily attained by manual operation. This air motor option is now available on most Kurt vises, including the all-new DX6 vise, plus most of their single station and double station vises ranging in sizes of 4 in, 6 in and 8 in models and is also available on smaller vise models such the SCMX420. Additional options are available for adding an encoder for programmability or an optional screw with double-start threads to increase stroke speed.

Kurt Manufacturing Company, Industrial Products Division, 9445 East River Road NW, Minneapolis, MN 55433, 877-226-7823, Fax: 877-226-7828, workholding@kurt.com, www.kurtworkholding.com.