Cost-Effective, Flexible Automated Welding Systems

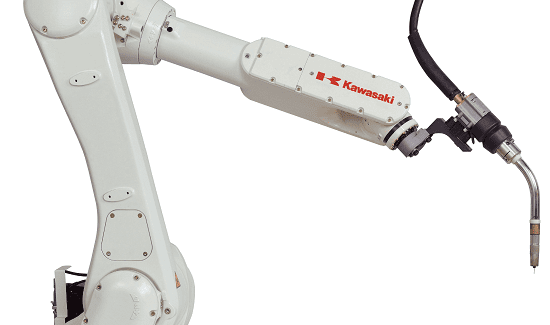

Arc welding robots from Kawasaki Robotics use state-of-the-art technology to match the quality of an expert welder so that a shop can quickly integrate robotic welding into their current processes.

Posted: August 19, 2019

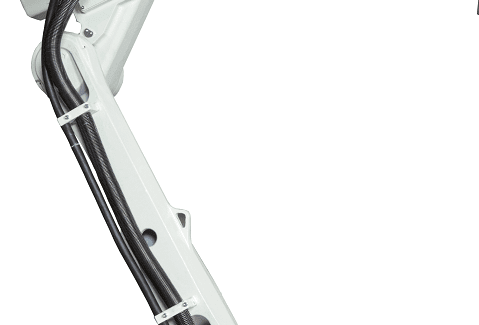

In Booth B-17074, arc welding robots from Kawasaki Robotics (USA), Inc. (Wixom, MI) use state-of-the-art technology to match the quality of an expert welder. On display will be examples of offline programming and seam tracking technology in one of their arc welding exhibits that features a BA006L arc welding robot equipped standard with arc welding specific software to enable quick and easy programming of the process path. Adaptive welding functionality is available to modify robot position, weave pattern and speed during welding to fill variable joints. Their built-in intelligence, flexibility and high accuracy make these arc welding robots ideal for a wide range of arc welding applications. Also on display will be a cost-effective and customizable pre-engineered robotic cell performing live arc welding to show how a shop can quickly integrate robotic welding into their current processes. Kawasaki offers standard and easy-to-use welding interfaces that can be integrated with any major brand of power supply.

Kawasaki Robotics (USA), Inc., 28140 Lakeview Drive, Wixom, MI 48393, 248-446-4100, Fax: 248-446-4200, kawasakirobotics.com.