Next-Generation Teachable Cobots Improve Machine Tending and More

OB7-Max 8 and OB7-Max 12 seven-axis smart collaborative robots from Productive Robotics add an enhanced human sense of vision that provides unique, flexible and cost-effective capabilities not currently available in the market.

Posted: August 8, 2019

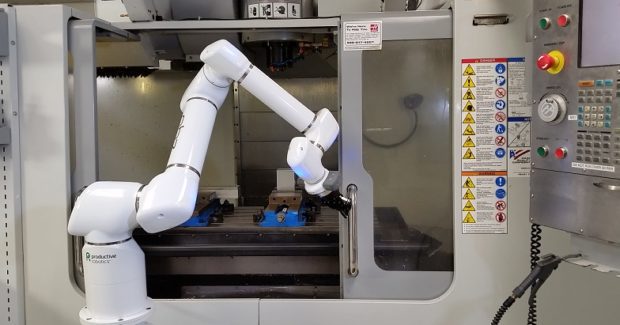

Flexible and cost-effective OB7-Max 8 and OB7-Max 12 smart seven-axis collaborative robots from Productive Robotics, Inc. (Carpinteria, CA) add an enhanced human sense of vision to the teach-and-learn platform that provides unique capabilities not currently available in the market. Equipped with innovative “no programming” OB Vision, simple-to-teach intelligence and human arm flexibility, these two cobots can handle larger payloads with long reach, at 8 kg and 1,700 mm, and 12 kg and 1,300 mm, respectively. Equipped with OB Vision, a human-like sense of vision for simpler, faster and more efficient robot training and operation, the cobot automatically learns to recognize and pick up objects with a single button push. The user simply shows OB7 how to do the job and the cobot learns, providing operators with complete ease of use.

OB7 offers ultimate flexibility thanks to its seventh axis. Like a human arm, seven joints give the cobot flexibility and dexterity to reach around objects or obstacles where others can’t. Unlike a human arm, each of joint on the cobot can rotate 360 deg in both directions. This allows the cobot to work in more confined work spaces and areas that a six-axis robot can’t reach. The OB7 will soon be equipped with an improved sense of touch.

Productive Robotics, Inc., 1033 Cindy Lane, Carpinteria, CA 93013, 805-244-9300, www.productiverobotics.com.